SigmaNEST works with every type of fabrication machine. Our software is engineered to enhance your production capabilities with smart features that protect your machine and produce superior quality parts.

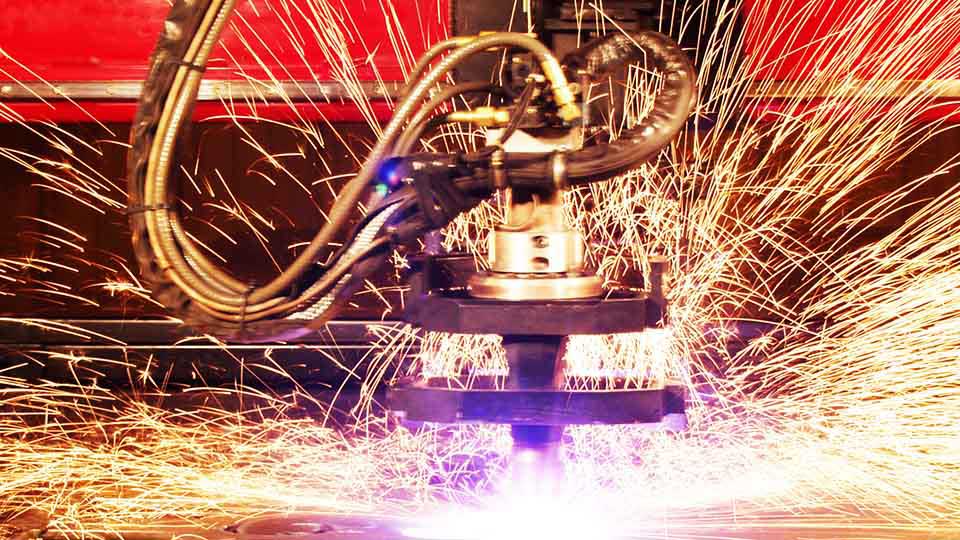

Maximize your plasma cutting machine’s capabilities using advanced features such as BHQ™ for precisely rounded holes.

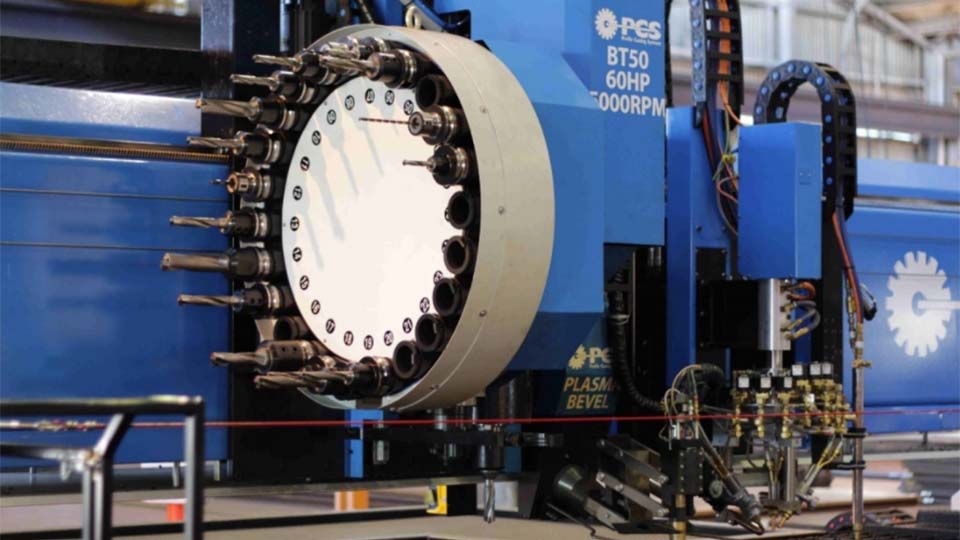

Use SigmaNEST nesting software to handle advanced processes such as heavy plate burning and multi-torch beveling.

Achieve faster cut times and eliminate tailwash without sacrificing on edge quality and material integrity.

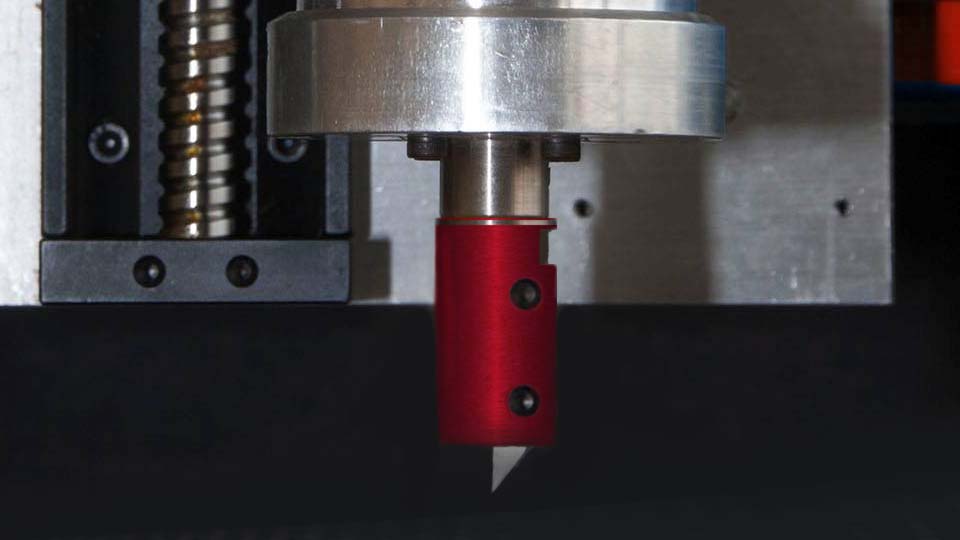

Extend tool life and lower costs while effectively programming single or multi-spindle machines to cut wood, composites, and other specialty materials.

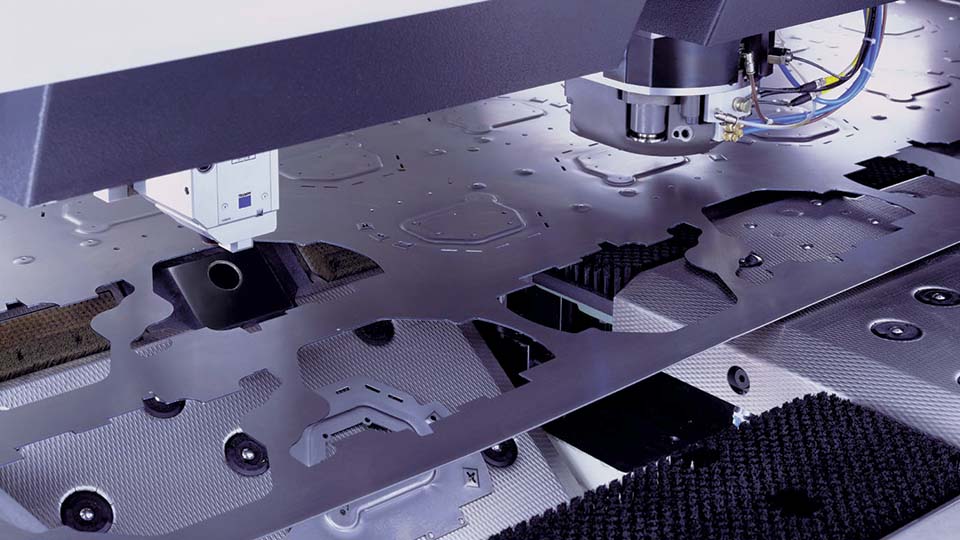

Run even the most complex punch machines while minimizing tool changes and shortening production time.

Use advanced knife cutting technology to achieve unmatched material yield through tight and accurate nesting.

Program your tube cutting machines using SigmaTUBE, a complete tube and pipe cutting solution that operates seamlessly inside SOLIDWORKS.

Maximize the speed, quality, and flexibility of your bending process using SigmaBEND, a complete press brake solution.

Use flexible tools and advanced features to automatically and easily program your punch combination machine.

No matter your machine type, SigmaNEST offers automatic nesting and programming for all custom features and capabilities.

SigmaNEST advanced nesting software optimizes the detailed features of bevel cutting machines to support superior part quality while reducing or eliminating scrap material.