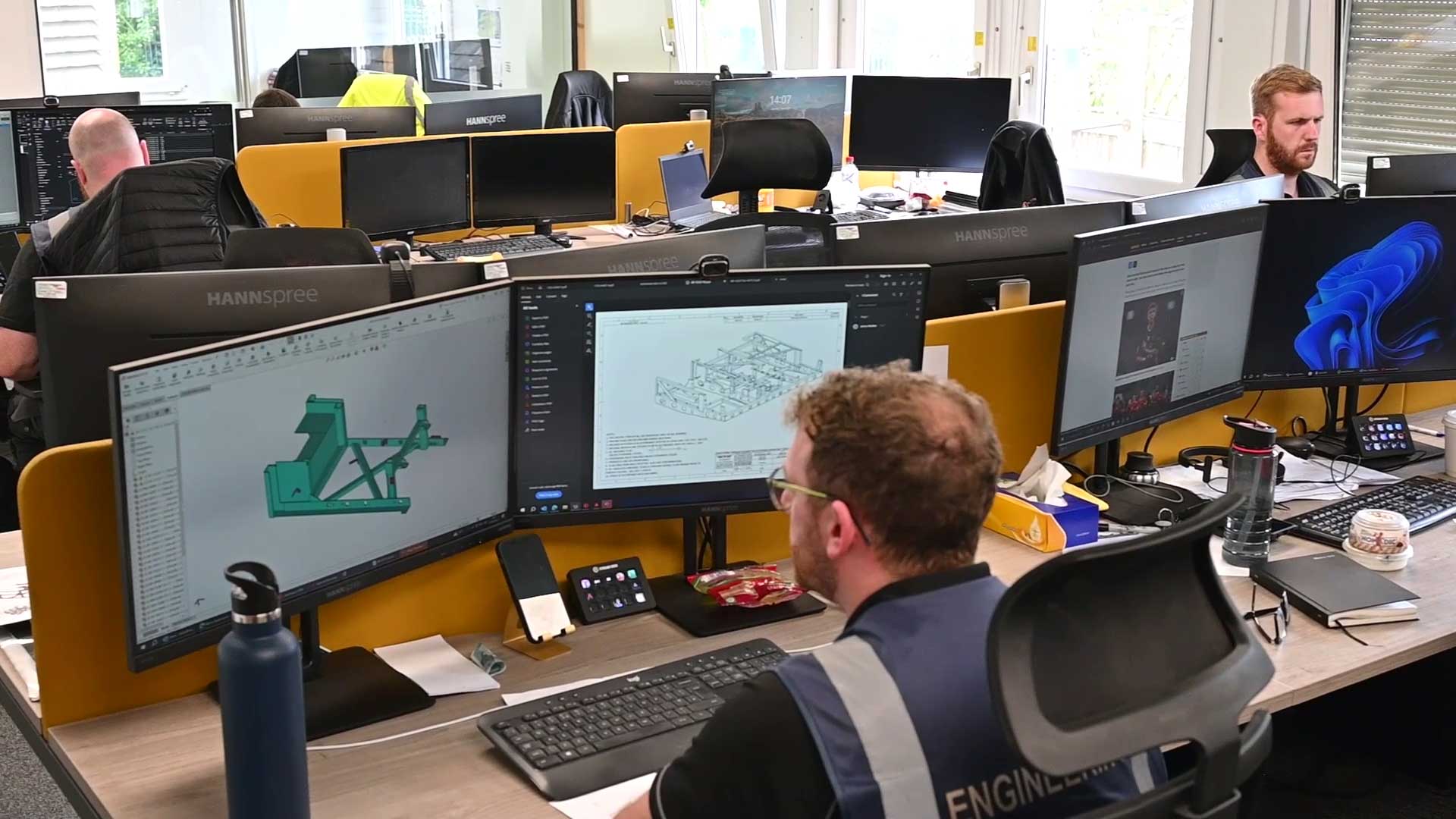

For more than 25 years, SigmaNEST has worked alongside fabricators to keep production running efficiently. Version 26 continues that commitment—delivering faster performance, smoother programming, and reliable nesting so your machines stay cutting and your business stays moving.

Whether you’re a production manager, programmer, operator, or executive, this release strengthens every step of production with connected workflows, smarter automation, and stable performance you can count on.

SigmaTEK 26 Suite delivers major benefits in speed, automation, integration, and usability.

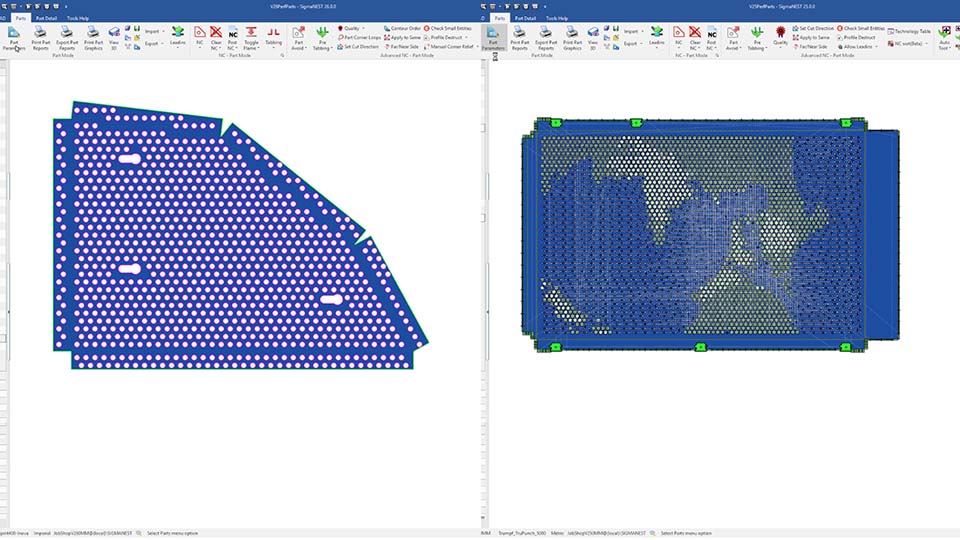

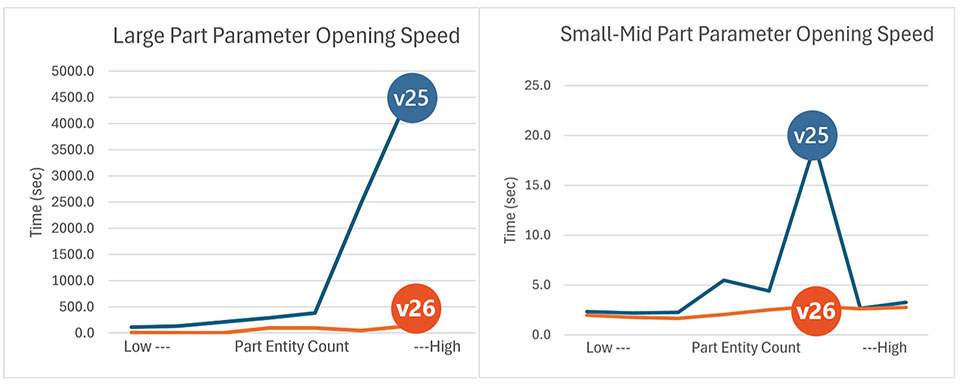

One of the most significant upgrades in Version 26 is the optimization of part parameter dialog loading. For daily users, what used to take up to 10 minutes now loads in just 20 seconds—a 99.7% reduction in wait time. This means less downtime, faster decision-making, and smoother programming operations for everyone on the shop floor.

Operators and daily users benefit from deferred data loading, which minimizes waiting and maximizes cutting time. This empowers users to focus on production rather than system delays.

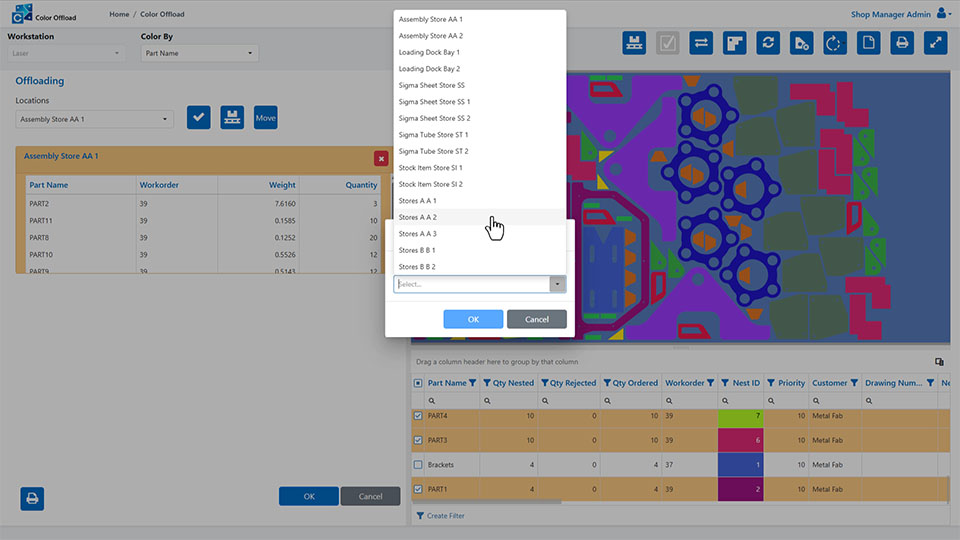

Production location tracking now allows users to assign physical locations to production items after each operation. Integrated with Color Offload and SFDC, this feature improves traceability, accountability, and lean manufacturing practices by keeping production organized and flowing efficiently.

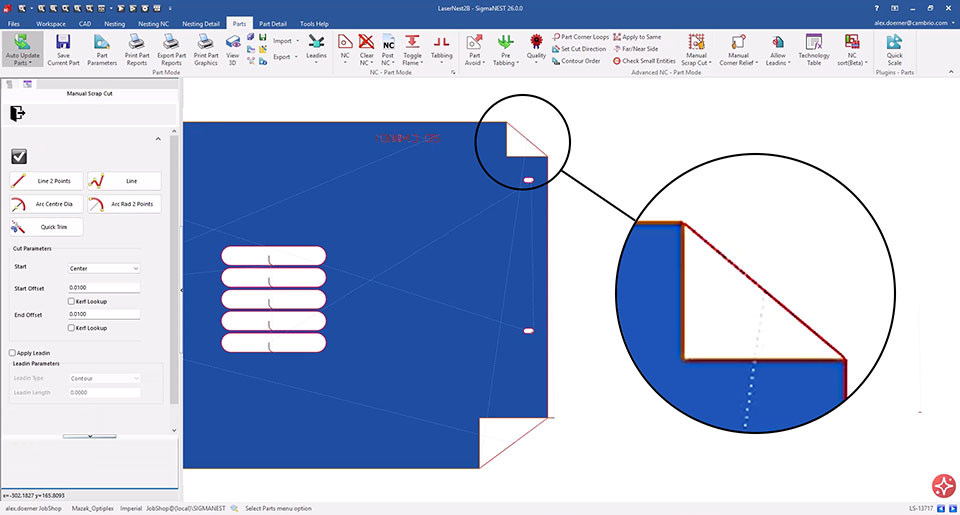

For operations managers and machine operators, new corner relief cuts and manual scrap cut features work together to ensure parts are cleanly released from the skeleton and scrap is broken down into manageable pieces. This reduces the risk of tip-ups, stuck parts, and machine interruptions, supporting both manual and automated unloading environments. Corner relief cuts improves part removal by adding small relief cuts around sharp corners or irregular cutouts, preventing parts from getting stuck in the sheet skeleton.

Users can define additional cuts to break down scrap material around dropped-out contours or corner reliefs, ensuring clean separation and safer cutting conditions. This is especially valuable in automated unloading systems.

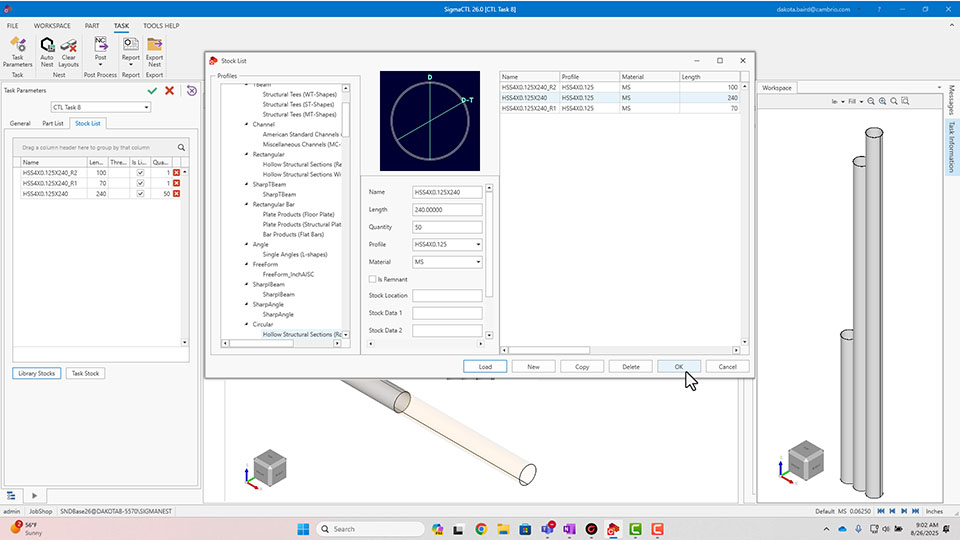

SigmaCTL now automatically prioritizes remnants before new stock, helping steel service centers reduce remnant storage and maximize material usage. This streamlines operations and cuts waste.

Advanced 3D bevel features like Break Edge, Split Loop, and Edit Leads give users precise control over bevel toolpaths. These tools allow for manual refinement of bevel sequences after NC has been applied, supporting intricate geometries and challenging bevel requirements. SigmaNEST’s rule-based consistency combined with manual control ensures optimal cut quality and reliable machine performance.

Pre-piercing can now be performed by part, group, or entire sheet, giving operators and programmers greater flexibility in managing pierce sequencing. This reduces nozzle contamination, cut defects, and supports safer, more consistent cutting.

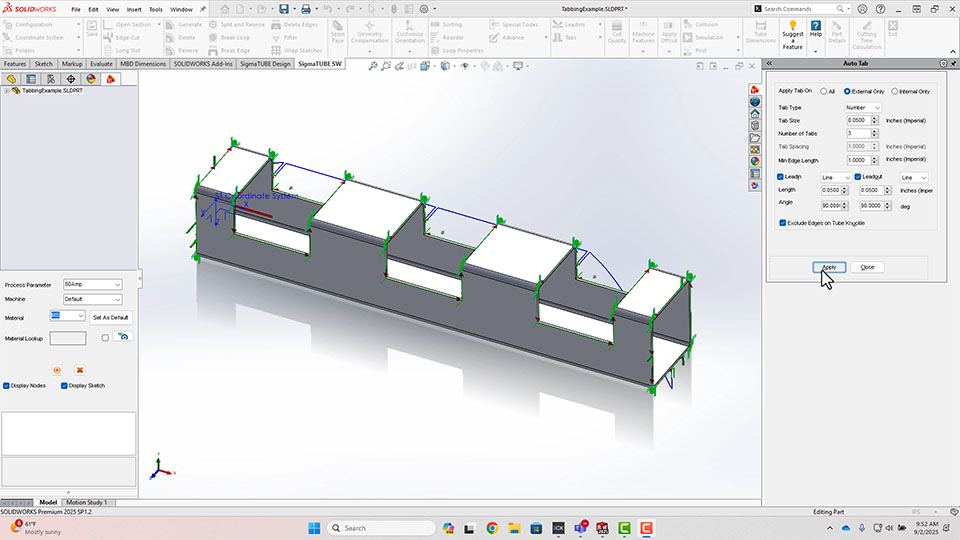

Programmers can now selectively tab either end cuts or internal features, reducing unnecessary tabs and improving cut quality.

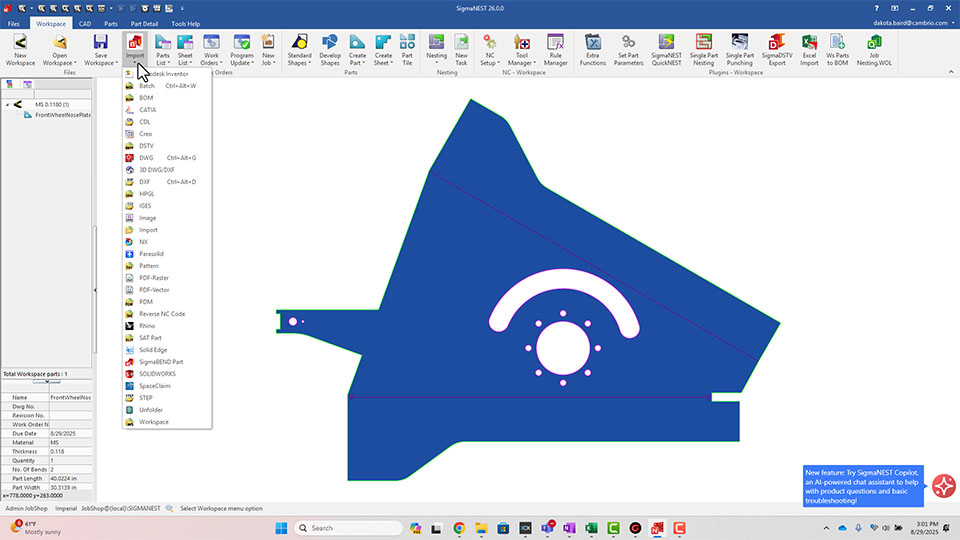

Engineers and programmers gain expanded support for SigmaBEND .polp files, Creo representations, partial depth as marking in STEP/CAD Import Plus, and DSTV bevel export. These enhancements eliminate manual data entry, improve data consistency, and ensure smoother CAD-to-CAM integration.

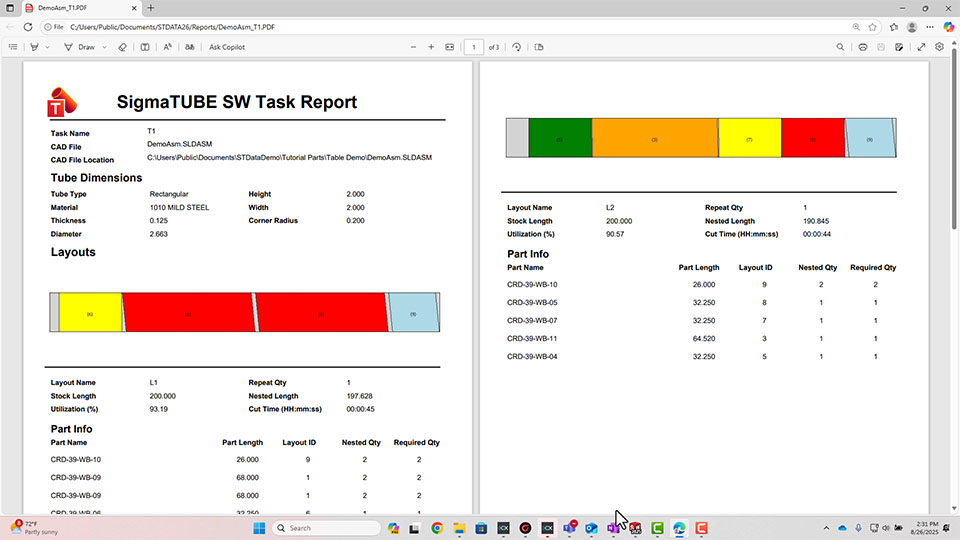

SigmaTUBE SW introduces smarter rule creation for automatic probing, identifying when loops fall within cutting boundaries and validating based on probe spacing. This prevents improper or excessive probing, improving accuracy and efficiency.

Customizable report naming and layout image overlays with part IDs make it easier to track parts and cross-reference layouts, improving traceability and flexibility.

IT and system administrators benefit from SimTrans Copilot, which introduces natural language support for faster troubleshooting. Optimizations reduce memory load and improve stability when handling massive datasets.

Enhanced licensing and automation controls give IT teams confidence at scale, supporting future growth and integration across SigmaNEST solutions.