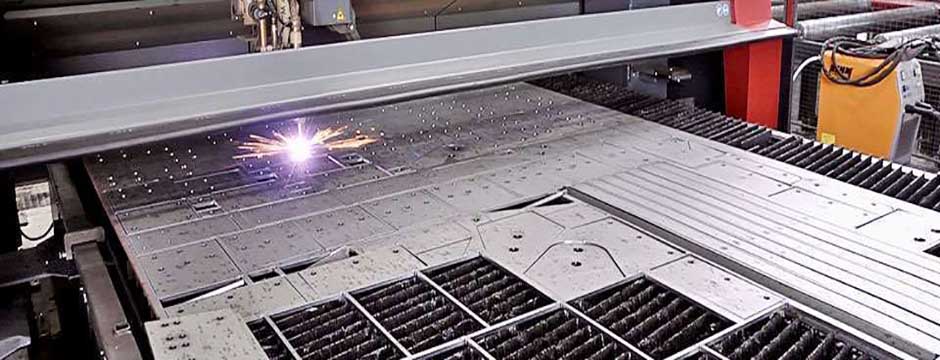

Voortman offers the advanced nesting engine SigmaNEST for their plate cutting machines for increasing material optimization and cutting efficiency. Advanced nesting algorithms ensure a better part yield and maximize material usage while optimizing the cutting cycle times.

SigmaNEST can be used for all types of cutting processes among others laser, water-jet, oxy-fuel and plasma which enables users to nest with only one program for all their cutting machines.