It was important for us to find a nesting software like SigmaNEST to help us become more productive and error free. We can now re-shift our focus back on providing the best products for our customers. We fully trust SigmaNEST to outperform on every job we send to our machines.

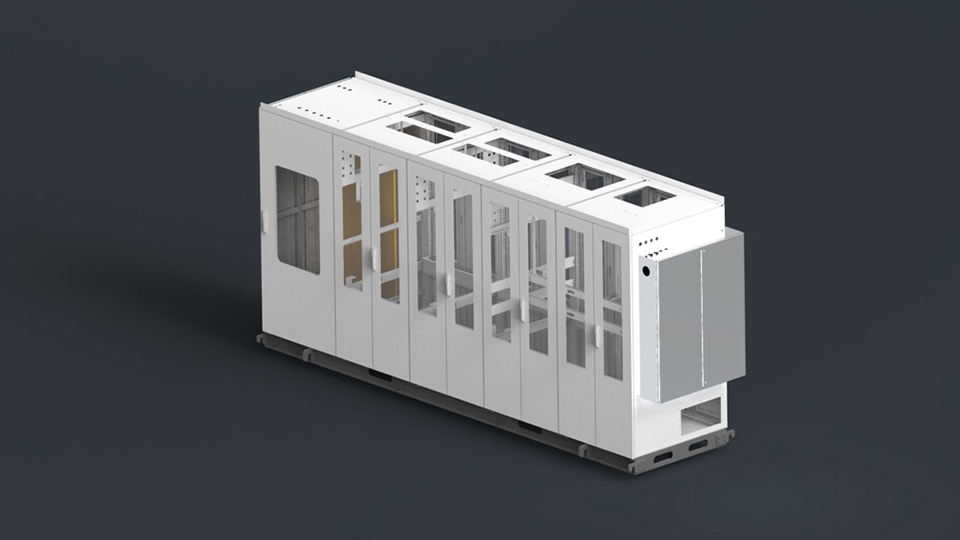

Founded in 1987, Powertrans Automation has been trusted for its quality, technical expertise, and timely delivery in both Private and Government centers. Powertrans serves sectors ranging from oil and natural gas, to steel and electrical, and energy transformation, with solutions that include construction of 400kV electrical substations to designing custom electrical and automation panels, bus ducts, and sheet metal enclosures.

Powertrans Automation found that streamlined workflow has become increasingly crucial to efficient and competitive manufacturing and is one area for improvement that can greatly impact the bottom line. Even a seemingly simple change can often reduce the risk for manual error and provide a smoother workflow that drives results.

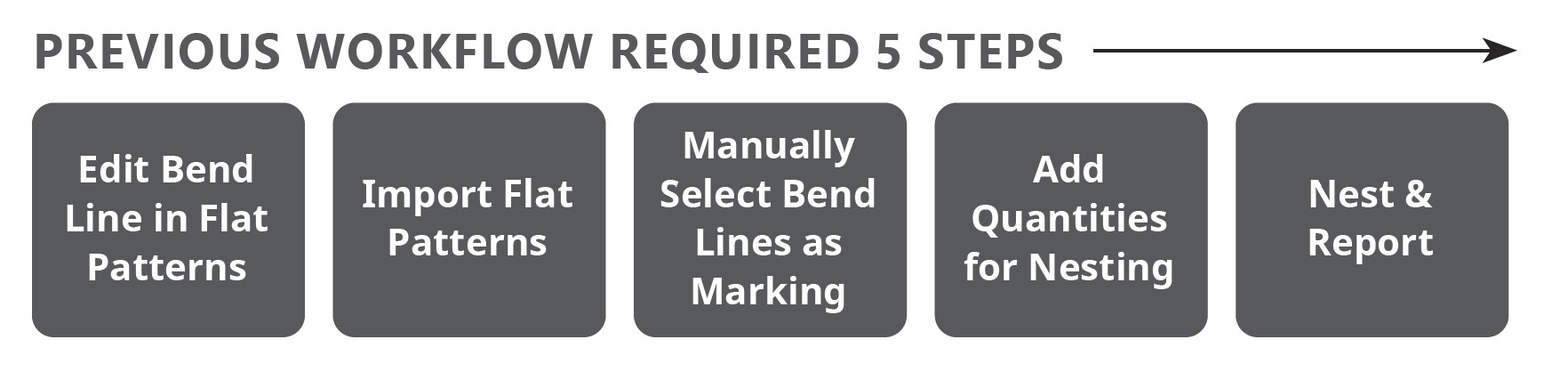

Before using SigmaNEST, Powertrans Automation was using CAD/CAM software supplied with their CNC laser machines. At the same time, they faced recurring challenges with part tracking, confusion over bending versus cutting lines on CAD drawings, and frequent bottlenecks in the reporting process.

The first challenge was to find a better way to keep track of parts and remnants. Many projects reached the end of the production phase only to find that parts were not cut or were missing. The project then stalled and waited for production for just one piece. This caused a lot of interruption to the production lines and significantly increased the delivery time for their customers.

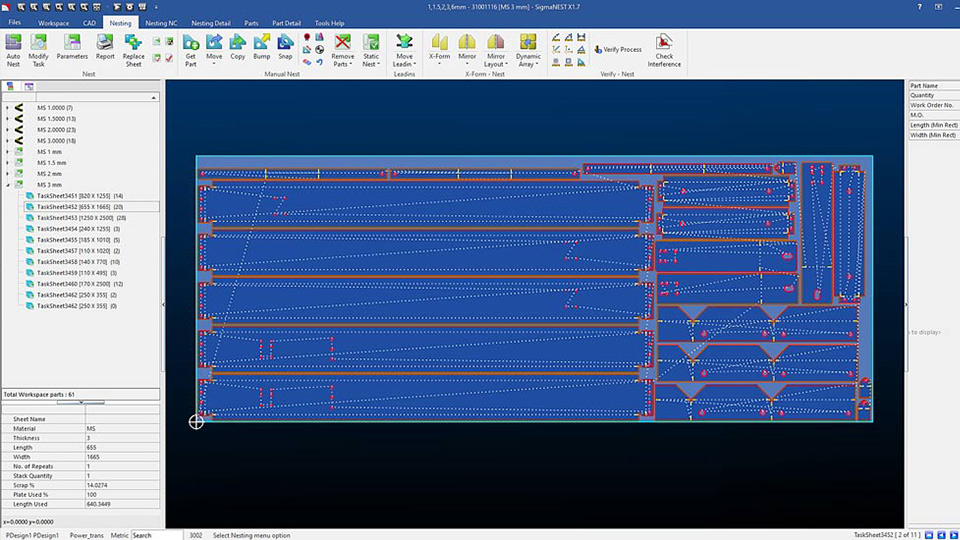

With the installation of SigmaNEST and its integrated part tracking capabilities, the programmers can import and view all of the parts needed to nest, cut, and bend, in one complete listing. Any errors that were due to manual entry and tracking are now eliminated from the production process.

“As nesting time is reduced, our lead time is reduced. We can focus on the designing of the product and worry less about potential errors and manual interference. These new processes help us reduce shortages in material and provide a smooth production flow. With SigmaNEST, our nesting time was reduced by 66%.”

SigmaNEST has provided us with the ability to improve our processes in a way we never thought was possible. They have equipped us with features that provide us with an edge in the competitive markets we serve.

A second challenge Powertrans Automation faced was in programming for the press brake. Programmers often had trouble differentiating between CAD lines for laser cutting and those that were bending lines for the press brake. Before integrating SigmaNEST, two separate processes were needed for cutting and marking. The programmer was required to manually select the bend lines based on two drawing points and then mark a separate line for bending. This was very time consuming and created a workflow bottleneck as two separate processes were being performed for one step in production.

SigmaNEST was able to transform this process from a two-step manual operation to one automated process. This has improved Powertrans Automation’s performance and profitability, saving time, reducing manpower, and eliminating the risk of human error. “Although we are currently only using SigmaNEST to optimize a single process, our complete manufacturing line is dependent on this operation,” explains Ankush Khemesara. “With our old nesting software, our processing time was 4 hours. However, with SigmaNEST our processing time has been reduced down to just 1 hour and 20 minutes.”

Nesting time was reduced from Day 1. We had less interference in manually moving parts on our sheet to get scraps, and as we gained a better understanding of SigmaNEST we created a standard procedure to fit our process which has streamlined our operations.

“Although we are currently only using SigmaNEST to optimize a single process, our complete manufacturing line is dependent on this operation,” explains Ankush Khemesara. “With our old nesting software, our processing time was 4 hours. However, with SigmaNEST our processing time has been reduced down to just 1 hour and 20 minutes.”

Lastly, Powertrans Automation has a much more robust reporting system with SigmaNEST’s comprehensive reporting capabilities. With SigmaNEST, they are now able to create customized reports that are unique to each customer, job, and part. Powertrans has created a handful of report formats that allow them to gather all relevant job information. These reports tailor their production schedule to each customer so they know exactly where in the production process a specific customer job is at any given moment. This has helped Powertrans to meet or exceed deadlines, inform customers which stage of production they are in, and deliver the best service possible.

Concluding, Khemesara says,“The integration process has run very smoothly. SigmaNEST has an excellent support team, and they provide immediate support which has already helped us tremendously. The improvements we have already seen with SigmaNEST helping to drive our production have significantly increased our time management, manpower, and bottom line. We look forward to continuing our partnership with them and potentially adding new products in the future.”

Company: Powertrans Automation

Industry: Electrical components and enclosures

Website: https://powertrans.io/

Key benefits achieved:

Smucker Laser enhances efficiency and control in metal fabrication by integrating SigmaNEST with SigmaMRP, improving quoting accuracy, job tracking, and overall operational management.

Tosec, a metal processing company in Zwolle, in the Netherlands, employs around 100 people and uses SigmaNEST solutions for efficient sheet metal processing and sustainable production.

Hutchinson Engineering Ltd. has implemented SigmaNEST, a comprehensive software solution for sheet metal fabrication, which has streamlined their operations, improved efficiency, and significantly reduced the quotation process.

Microlaser Srl implemented SigmaNEST and SigmaMRP software, leading to leaner and faster production with improved workflows and reduced order processing time.

Mecal Srl reduced their programming time by 300% by implementing SigmaTUBE and SigmaNEST, resulting in improved efficiency and integration with their management system.

Powertrans increased productivity and reduced errors by implementing SigmaNEST for automated nesting, tracking, and reporting. The software enabled competitive manufacturing with streamlined workflow and customized reports.