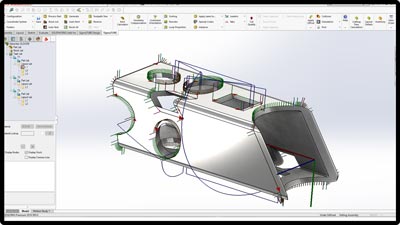

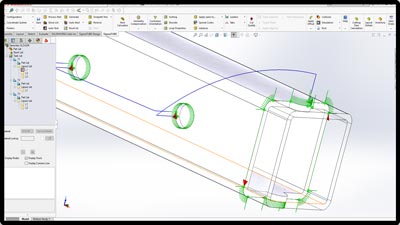

With the ability to break down an entire tube assembly, SigmaTUBE SW can separate parts by nesting tasks, nest each part for optimum yield, and apply advanced toolpath techniques all in a matter of seconds. SigmaTUBE software supports laser and plasma cutting for tubes of any shape along with all common structural profiles.

SigmaTUBE SW automatically examines the entire assembly to identify which parts are applicable for programming. Parts are then automatically grouped according to their profile and material. Quoting the complete part assembly is made easy by integrating SigmaQUOTE to provide support for costing and scheduling work orders.

![]() = Module Included,

= Module Included, ![]() = Module Optional

= Module Optional

| AutoNest | TrueShape | Techno | PowerPack | |

|---|---|---|---|---|

| Geometry Modules | ||||

|

Generate standard dimension driven tube shapes with miters, copes, and common tube assembly structures. |

||||

| Toolpath Modules | ||||

|

Automatic toolpath generation for single part runs. |

||||

|

Generate geometry compensated toolpath to trim away extra material on bevel geometry for a perfect weld fit without cutting true bevels. |

||||

|

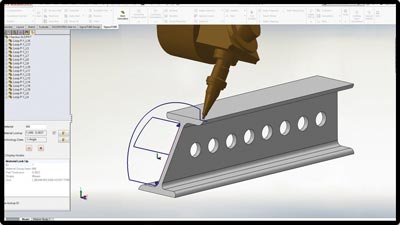

Generate 5-axis toolpath for bevel cutting machines for a true to model finish. |

||||

|

Program advanced NC capabilities like auto cut quality and toolpath generation for open section toolpath. |

||||

| Nesting Modules | ||||

|

Length-based nesting for optimum material yield on straight end cut geometries. |

||||

|

Improved material yield by flipping and rotating parts for a true-to-geometry nest for miter, cope, and complex geometry end cuts. |

||||

| Productivity Modules | ||||

|

Complete material inventory management with remnant tracking |

||||

|

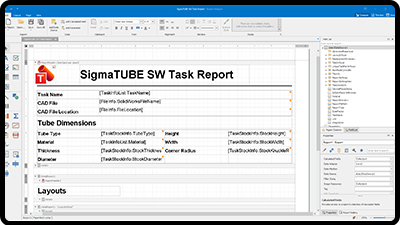

Streamlined job tracking with scheduling, autoloading parts for nesting, and updating orders with actual parts cut. |

||||