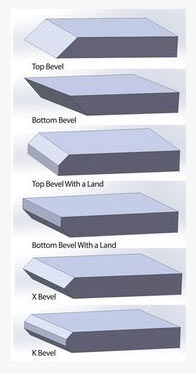

Bevel cutting commonly refers to the cutting of a part with an edge in such a way that the edge is angled in relation to the surface of the part. It is done to allow a greater surface area on the edge for welding preparation and other final assembly methods, each with its own set of challenges.

Additionally, thermal cutting, abrasive cutting, and machining all have a completely different set of considerations when performing bevel cuts on plate, tube, wood, composites, and so on. Regardless of how simple or complex the part is the process requires experience and a thorough understanding of machine and material.

What makes the bevel so different from a traditional 90-degree cut is that at any given time at least three, and sometimes four, variables are always in play: feed rate, tilt angle, kerf offset, and sometimes arc voltage. Each must be held within tight parameters for a successful bevel cut. The process can be overwhelming for even the most advanced programmer.

SigmaNEST advanced nesting software optimizes the detailed features of bevel cutting machines to support superior part quality while reducing or eliminating scrap material. By combining an easy-to-use user interface with cutting-edge functionality for laser, plasma and waterjet machines, SigmaNEST is an ideal solution for beveling technology for both 2D and 3D applications.

Watch a recorded webinar hosted by SigmaNEST Project Engineer Oliver Lim. In 25 minutes you will learn more about SigmaNEST 3D Beveling.

For the most demanding beveled parts, the ability to visualize a 3D simulation of the entire nest can save time and avoid wasted material. SigmaNEST 3D Bevel module eases programming with a full 3D model of the machine cutting head as it cuts each part.