Fiber lasers have taken the market by storm. They promise faster, sharper, cleaner parts and less maintenance to boot. Operating costs are lower, and material yield higher. Optimize your process using SigmaNEST, the most advanced laser cutting software.

To get the results you were promised, machines can’t simply be run “as-usual.” Industry front-runners and machine manufacturers trust SigmaNEST to achieve optimal performance. SigmaNEST laser cutting software was created through years of targeted research and development with nesting and NC programming. We support all different types of lasers, from fiber and CO2 to tube or combination machines.

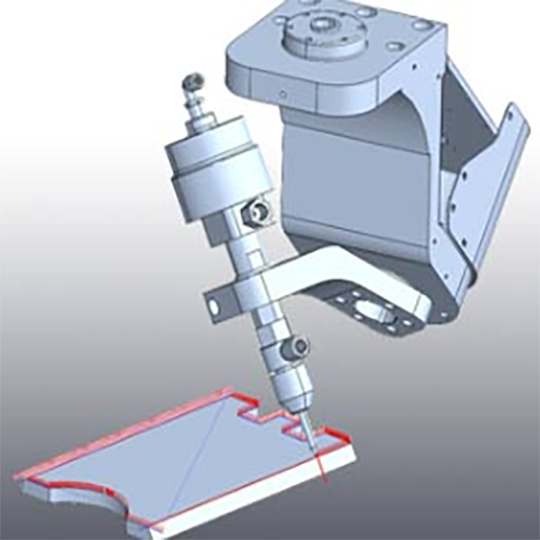

SigmaNEST BHQ™ improves on market-leading hole quality cutting strategies by offering both bolt-quality precision and optimization of taper, roundness, and machine runtime. Automatic lead-in lookup is based on hole size, material thickness, process type, and power.