Today’s advanced Plasma cutting systems require modern, robust software. SigmaNEST is full of unique features and capabilities to super-charge your plasma cutting fabrication machines. Our bolt hole cutting module, SigmaNEST BHQ™, provides unmatched plasma cutting for precise cylindrical holes.

Plasma cutting is the process of cutting through conductive material using an accelerated jet of hot plasma. Because Plasma is a high-speed and precision-focused cutting type, this method is often used in both large and small facilities. Materials cut typically include steel, stainless steel, aluminum, brass, and copper. In addition to developing totally unique features for plasma tables, SigmaNEST evaluates cutting parameters in real-time, providing automatic improvements in cut times, consumable yield, and edge quality. Get the best parts on any machine regardless of power supply and controller configuration.

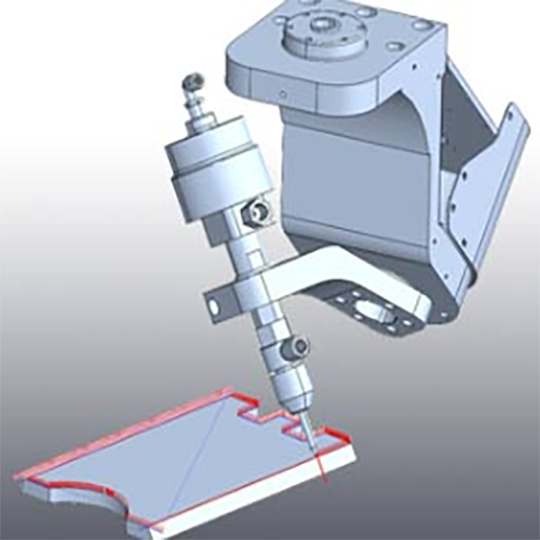

SigmaNEST BHQ™ improves on market-leading hole quality cutting strategies by offering both bolt-quality precision and optimization of taper, roundness, and machine runtime. Automatic lead-in lookup is based on hole size, material thickness, process type, and power.