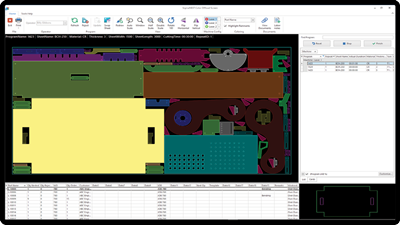

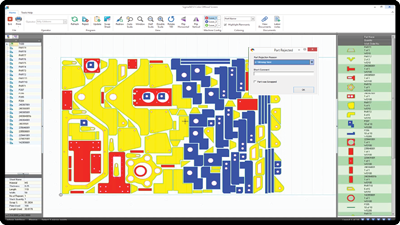

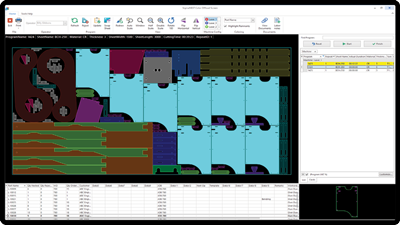

Make part unloading from your cutting machine faster and more accurate by color-coding parts. Color Offload eliminates confusion by displaying nested parts in colors that can be assigned by customer, work order, shipping address, or any custom designation.

Mixing work orders saves time and material, but also creates the potential for error when unloading and sorting parts. Using a clear visual diagram, Color Offload eases the burden of identifying parts by shape or number and allows quick handling to the next destination. Parts for each job are traced throughout production to final delivery. Shop floor momentum is sustained along with higher material yields and process efficiency.