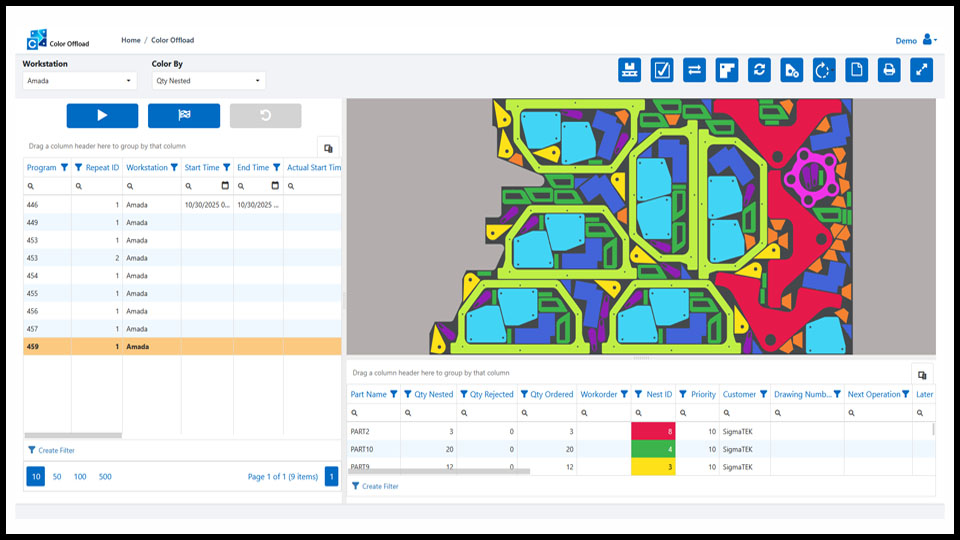

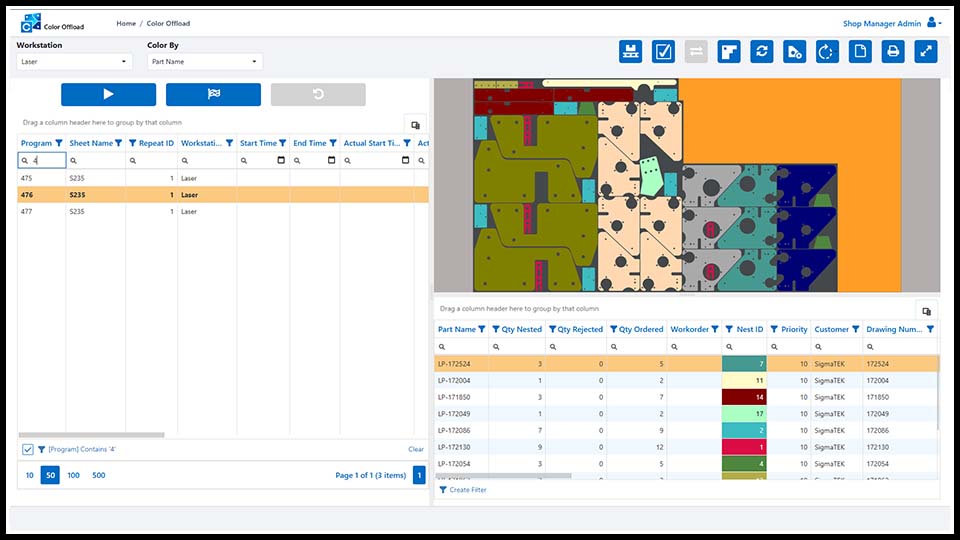

Color Offload is a local browser app within Shop Manager that simplifies part unloading and boosts shop floor efficiency. Designed for sheet metal fabrication teams, it transforms complex nests into interactive, color-coded graphics—making part identification, sorting, and unloading faster and more accurate.

By eliminating paper reports and replacing them with dynamic visuals, Color Offload reduces errors, improves communication, and keeps parts moving efficiently. Operators can assign colors based on job number, customer, next operation, or priority—bringing instant clarity to mixed work orders and complex nests.

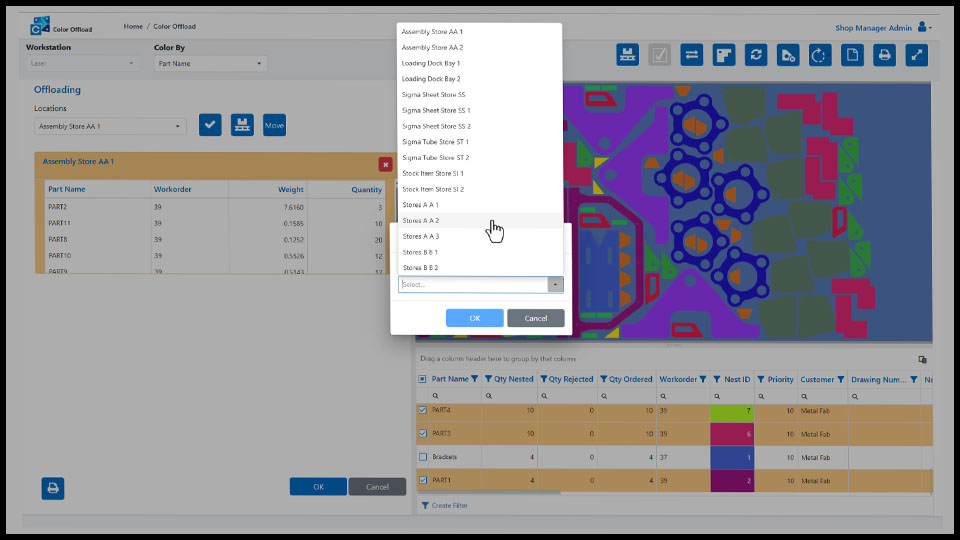

Color Offload turns unloading into a visual, intuitive process—keeping parts moving, reducing clutter, and improving accuracy. Whether organizing mixed jobs or tracking parts to final delivery, it brings clarity, control, and efficiency to the fabrication process.

Completed programs are automatically reported back to SigmaNEST, ensuring real-time visibility and smarter scheduling. Remnants are highlighted on the screen and are automatically added to inventory when the program is complete. Operators can update sheet data, record machine cut times, and view part details—all from a tablet interface with touch controls and an on-screen keyboard.

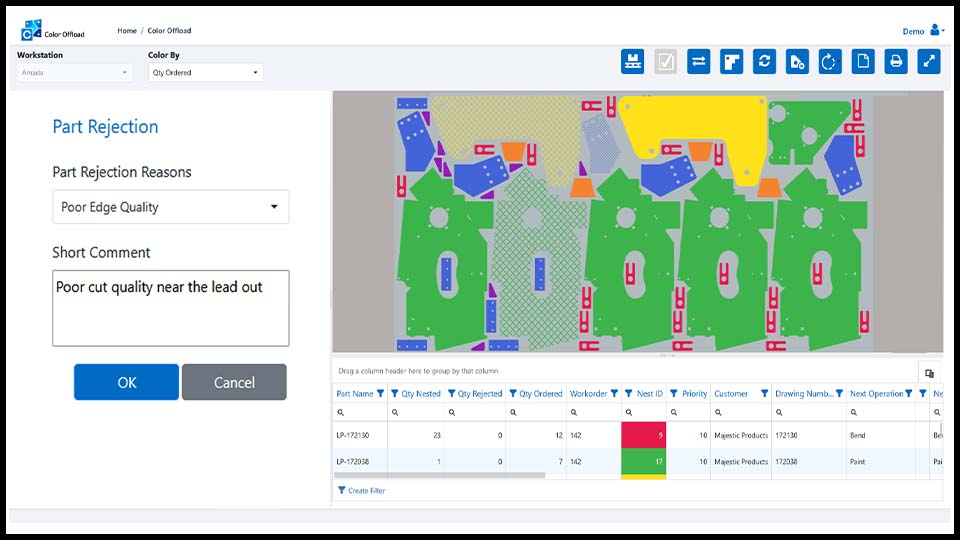

Operators can reject individual parts directly from the interface, instantly flagging issues such as poor cut quality. This feedback loop automates communication to quickly correct any errors.

When the specific sheet can’t be found or another sheet is easier to access, operators can swap inventory on the fly without interrupting nesting logic. This flexibility empowers operators to adapt quickly and keep production on track, while recording actual sheet use and ensuring accurate inventory.