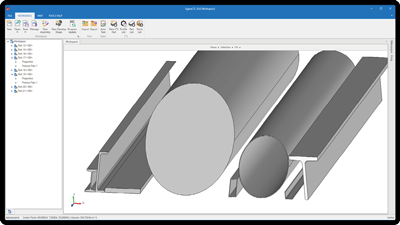

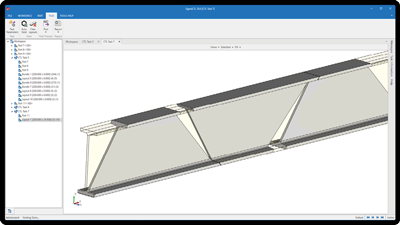

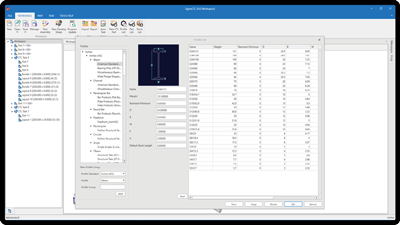

SigmaCTL is a Cut-to-Length nesting solution to allow fabricators to nest segments onto bar/tube/pipe/beam stock ensuring the most efficient use of material. Powerful nesting algorithms calculate an optimum cut plan when working with complex work orders and varying stock length and thickness.

With support for miter and bundle nesting, SigmaCTL offers scrap reduction, raw material/remnant tracking, and order processing to produce less waste and improve efficiency all with minimal user interaction. Miter support flips and rotate parts to match up miter geometry for a better nest.