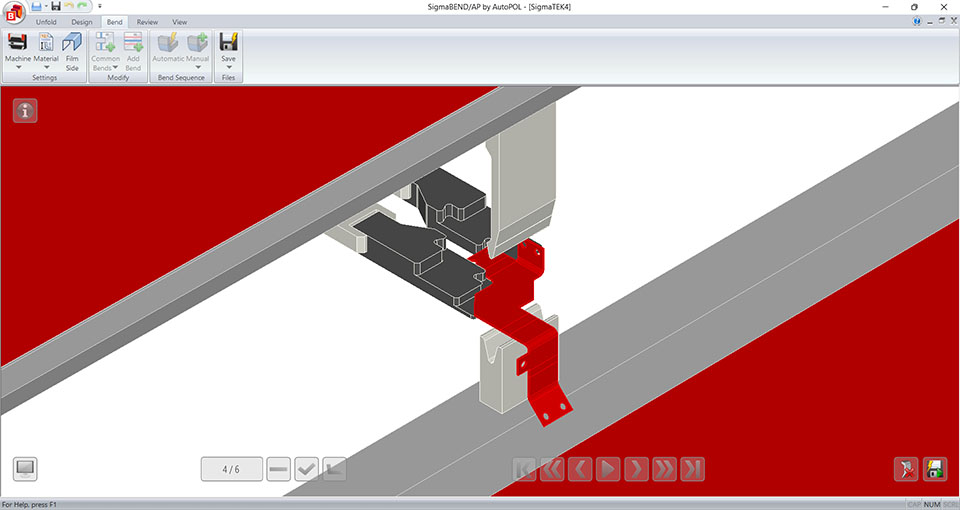

SigmaBEND AP utilizes full 3D simulation to maximize the speed, quality, and efficiency of press brake operations. The ability to interactively change programming parameters provides ultimate control. Verifying bending operations offline frees up valuable machine time, improves first-off reliability, and reduces manufacturing costs.

Through detailed bend instructions, even a less experienced operator can confidently bend a part accurately the first time, while being fully aware of the tooling and bend sequence prior to the start of the program—reducing scrap and delivering further efficiencies to the shop floor.

SigmaBEND AP provides an automatic programming solution to reduce the bend bottleneck through increased accuracy, optimization of setup and tooling, and standardized programming and bend sequencing.

![]() = Yes Supported,

= Yes Supported, ![]() = Not Supported

= Not Supported

| SigmaBEND AP BendSim | SigmaBEND AP BendSim Pro | |||

|---|---|---|---|---|

| Import | ||||

| 2D Import

Import 2D DXF files to create 3D models using an interactive import tool |

DXF Only | DXF,DWG | ||

| 3D Import

Import from a wide variety of 3D file formats including STEP, ACIS, SolidWorks, Inventor, SolidEdge, NX, Creo, Catia, IGES, JT |

STEP,ACIS | All Formats | ||

| CAD Properties

Detect CAD Properties during import to assign material automatically or filter assemblies based on file properites |

||||

| Assemblies

Import and break down assembly files using an interactive assembly processing tool |

||||

| Export | ||||

| 2D CAD

Export Flat pattern geometry to for use in SigmaNEST for cutting accurately sized blanks |

DXF Only | DXF,DWG | ||

| 3D CAD

Export update flat and folded geometry for a 3D CAD representation of the finished part as STEP or ACIS format |

||||

| General | ||||

| Industry 4.0 Data Sharing

Export additional part property information to an Industry 4.0 Data sharing XML for use in down stream operations or ERP integration |

||||

| Custom Properties

Populate custom property data on SigmaBEND model files to share using various export formats |

||||

| Dimensioning

Use dimensioning tools to measure distances on the 3D model |

||||

| Barcodes

Add customized barcodes to process documentation outputs to quickly link to posted NC programs |

||||

| Machines | ||||

| Machine Setup

Configure multiple press brake machines to use specific tooling libraries, controller post processors and customize ram and back-gauge movements |

Up to 2 Machines | Unlimited | ||

| Post Processors

Choose from a wide variety of preconfigured machines and post processors |

1 | All Supported | ||

| Advanced Machine Options

Configure angle measurement tools, front gauge supports, and heming tables for applicable machines |

||||

| Shared Settings

Share machine setups and settings via a network locaiton to ensure all workstations are in sync |

||||

| Unfolding | ||||

| Step Bends

Customize the unfold of large radius bends to create smaller individual steps in the unfolding and bending. Automated tools available in the Pro version |

||||

| Film Side

Specify film location on the 3D model to help indentify the part as it is flipped and rotated during programming. Automated tools available in the Pro version |

||||

| Assembly Processing

Unfold individual parts within an assembly file through an interactive processing tool. Automated tools are available in the Pro version |

||||

| Bending | ||||

| Pre-Bends

Add pre-bends to existing bends to help prevent collisons during the part bending |

||||

| Reverse Bends

Add bends to parts which are then reversed using a second unbending process to help prevent collisons during the part bending. |

||||

| Passive Bends

Assign bends as passive to let the software know they are already formed or to ignore them when programming. |

||||

| Add Bend

Add new bends to existing parts which were not present on the original models. |

||||

| Time Estimates

Customize setup and cycle time estimates for the bending process based on part sizes, weights, and other bending process details. |

||||

| Collision Detection

Collisions with the various elements of the machine and tooling are highlighted during the simulation to help reduce programming errors. |

||||

| Tool Libraries

Customize tool libraries with specific tooling profiles, segement lengths, and quantities to ensure accurate station setups. |

||||

| Add-ons | ||||

| Designer

Enhance your SigmaBEND AP package with the ability to create simple 3D sheet metal models and pipe sections from parametric shapes |

||||

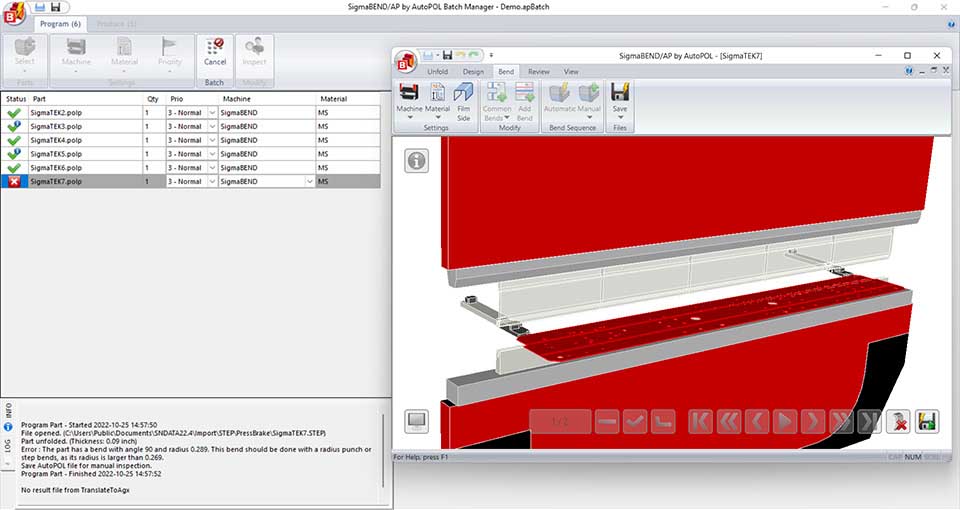

| Batch and Remote

Automate your bend programming even further with unattended processing of parts and assemblies and sequence your programs to reduce tool changes |

||||

| Network License Upgrade

Upgrade the license to support network sharing |

||||