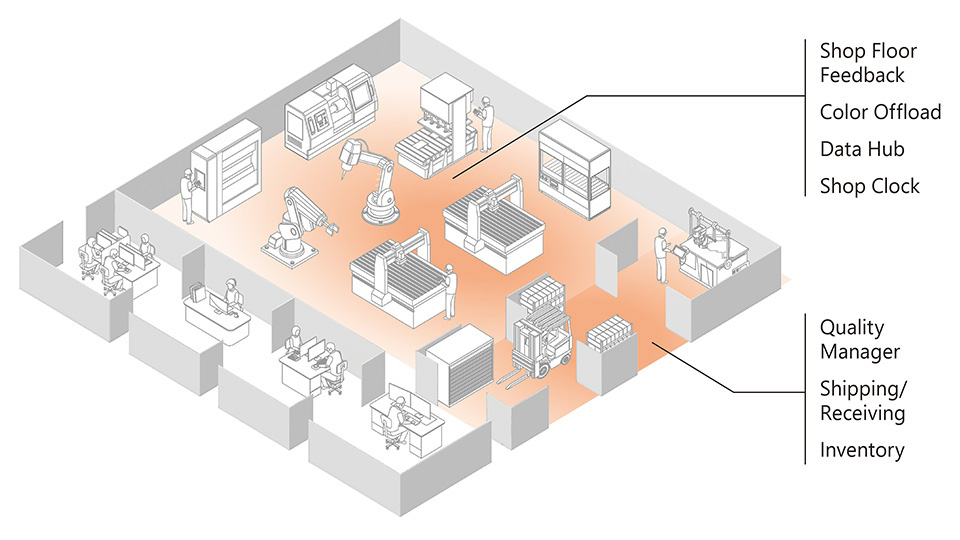

The Shop Manager apps enable browser-based access throughout the shop to simplify production and boost efficiency. By replacing paper reports with a dynamic data interface, Shop Manager reduces errors, improves communication, and keeps parts moving efficiently.

Shop Manager hosts a range of modular tools to expedite part offloading and quality, update production progress, and manage inventory, logistics and more. Shop Manager also tracks job status in real time everywhere in the shop for informed management. Shop Manager is hosted onsite for secure shopwide communications.

Shop Manager delivers better visibility and control across your operations. Its seamless integration and flexible design empowers teams to reduce waste, make faster decisions, and scale with confidence.