Transforming data into useful information is simplified with a comprehensive suite of software

We’re living in a digital world, and the manufacturing industry is no exception. To stay competitive, businesses within the industry are embracing automation, Industry 4.0 tenets and a cache of digital strategies that all require the collection and analysis of data – and lots of it. Leveraging this information provides insight to streamline operations, maximize investments, and generate measurable and sustained improvements across the board. On the other hand, how does a typical fabricator identify and access the right information? And how is that data best put to work?

SigmaNEST software suite, a brand found in the Sandvik Manufacturing Solutions group, is helping to solve this problem by converting essential data into actionable insights to bridge communication gaps and transform workflow management. I recently spoke with Dakota Baird, product owner at SigmaNEST, to learn more.

I assume the great majority of fabricators are taking advantage of some level of automation. Is this correct?

Absolutely. No matter if you’re talking about an OEM, fab shop, job shop or metal service center, today’s manufacturing landscape is becoming increasingly automated and, therefore, data dependent.

While more data has its advantages, it can quickly become overwhelming. The key is to extract what’s pertinent and transform this data into useful information that will optimize workflow. It is, therefore, critical that the data driving your processes, communication and decisions is relevant, complete and accurate.

While more data has its advantages, it can quickly become overwhelming.

That’s a great point. What do you mean by useful information?

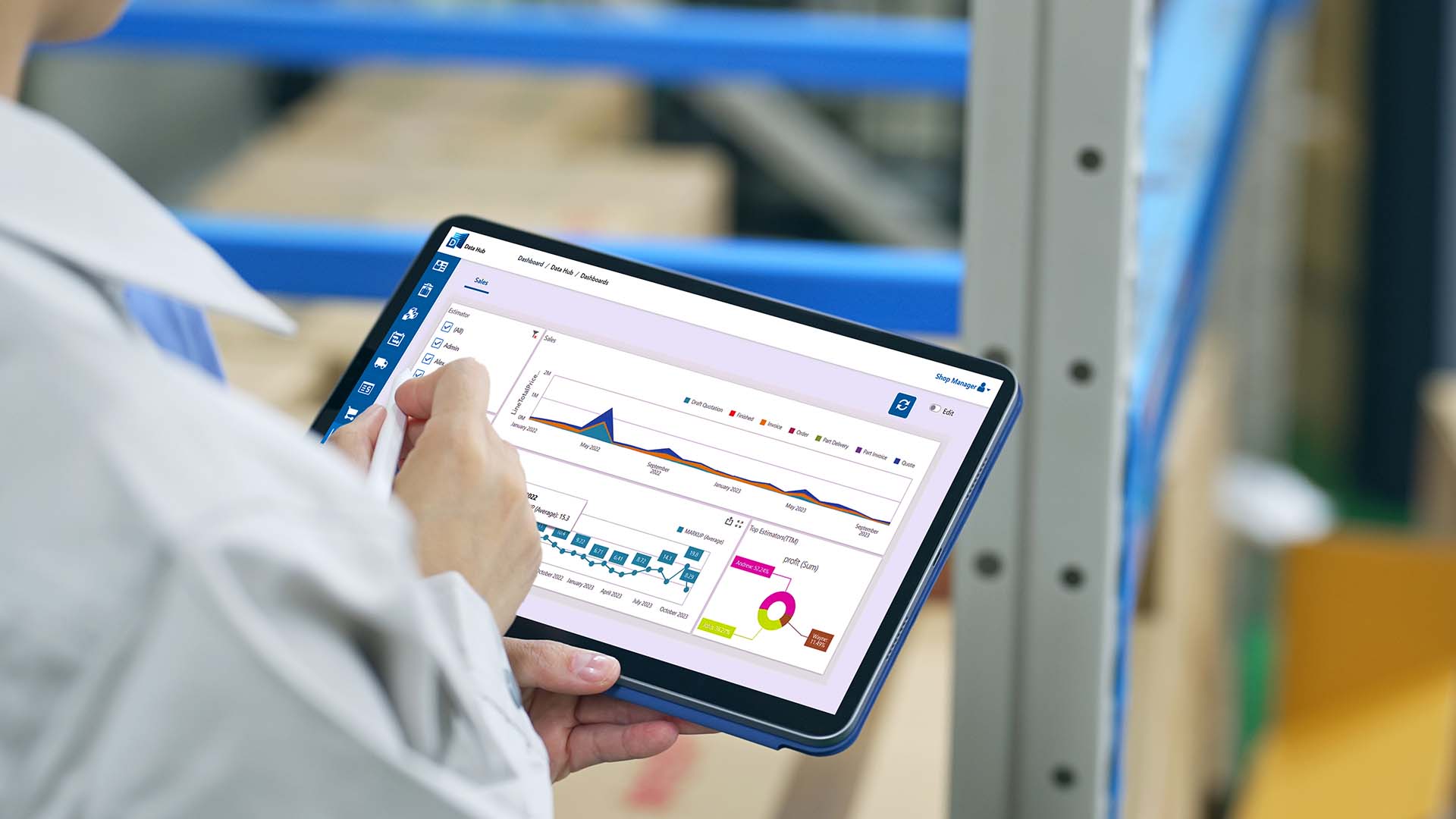

I’m talking about making data accessible so that it’s in a form that makes sense. It needs to be transparent and readily accessible upstream and down. For example, with our Shop Manager application, which is part of the SigmaNEST software suite, supervisors and management have the insight to better manage jobs by instantly knowing the progress of a job, when it’s scheduled to run, ship and so on.

So, Shop Manager, for lack of a better way to put it, manages shop activities?

Yes. It’s a management tool that offers a high-level view of the shop and the business. Shop Manager dashboards chart jobs over a stretch of time or can be focused on a specific customer or job. The bottom line is to turn data into actionable information allowing fabricators to be more prepared and predictable.

We have out-of-the-box dashboards that display win/loss ratios of jobs over time and per estimator. We also have dashboards that show the scrap percentages and weight sold per material and thickness.

How does SimTrans, another part of the SigmaNEST software suite, fit into the process?

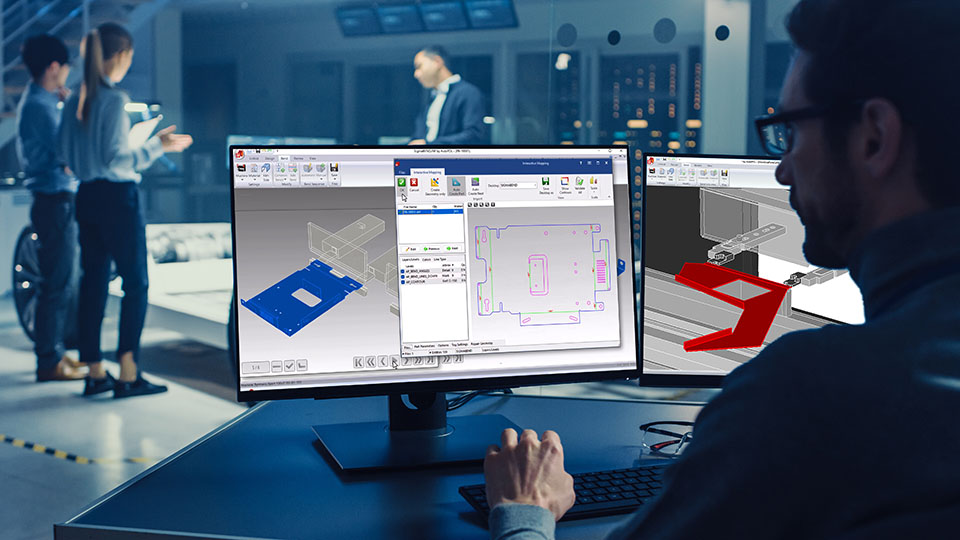

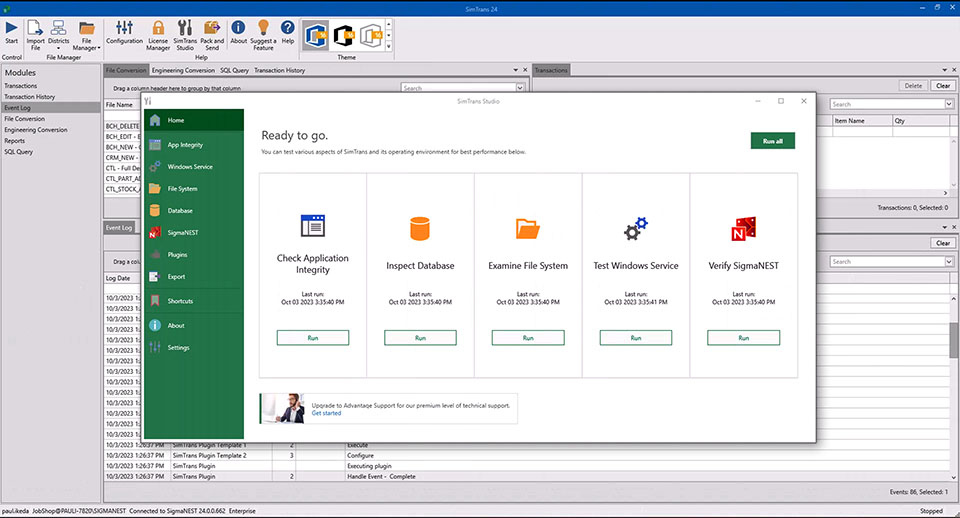

SimTrans centralizes and manages manufacturing transactions such as money, work orders, stock, bill of materials, files and more. Think of SimTrans as the connector between our SigmaNEST CAD/CAM software and an external ERP/MRP software.

It allows our system and the external systems to communicate and pass data back and forth, such as inventory and work orders. Of course to do this, it has all kinds of automation tools for interacting with SigmaNEST and our database.

Sounds good. But why not use a robust commercial ERP/MRP solution?

SigmaNEST fills a major gap within many “commercial” ERP/MRP solutions specifically, nesting and programming. These systems aren’t driving the actual cutting machines so this is where we can help.

With SimTrans, we can integrate with those ERP/MRP software options to pass data back and forth regarding the production. We also have a full suite of Business Systems software tools that replace many of the ERP/MRP software options on the market for our customers in the fabrication industry.

The most streamlined approach for most small to medium-size shops is to have the ERP/MRP software and nesting software fully integrated from the ground up without the need to exchange data from multiple systems. This is one of the solutions we offer.

Would you say that SimTrans is a great alternative for smaller fabricators that don’t need a full blown MRP?

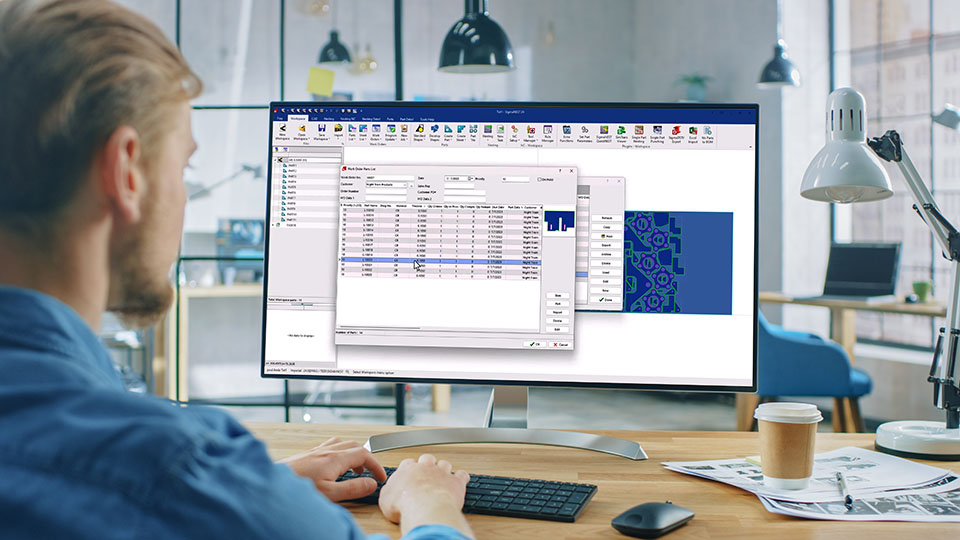

Perhaps a better question is “How does SigmaNEST help smaller shops?” SimTrans is a great solution if a shop has an existing ERP/MRP software they like and they want to integrate SigmaNEST software with that ERP/ MRP. It would certainly help them get data from their ERP/MRP into SigmaNEST to help streamline the production nesting step of the process.

If the shop is looking to implement an ERP/MRP software or streamlined shop management software then our Connected Shop manufacturing ERP solution could be a great choice. It brings CRM, quoting, nesting, production management and scheduling, purchasing, invoicing and deliveries all under one software roof.

It sounds like this could be a solution for manufacturers with labor shortages or high production demands.

That’s true. The workforce is changing and the industry remains understaffed. This means less time for training as workers must become productive more quickly. Our software bridges the gap making the information readily available, so they don’t have to decipher what’s going on and you don’t have people running around the building looking for information.

What does a typical implementation engagement look like?

SimTrans requires some setup and support from IT or a tech-savvy person. But once that’s done, it just runs. You tell it what you want to do, and it does it. With SigmaNEST 24, implementation is transparent to the user and easily customized.

For our Connected Shop solution, we partner our customers with a project manager to map out their business and implement workflows that work best for them.

SigmaNEST offers some new functionality. Can you elaborate?

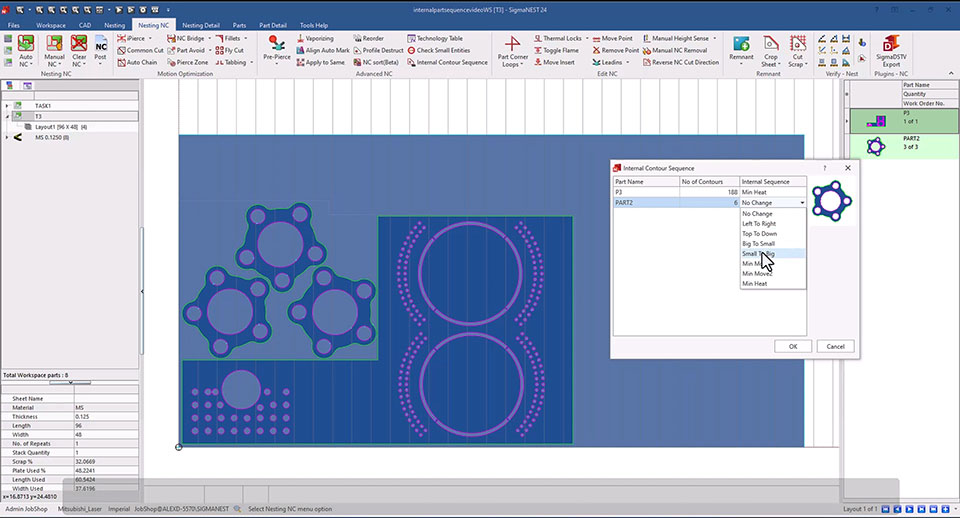

We have quite a bit of new features we’re excited to give our customers in our latest release. From the NC programming side in SigmaNEST, we’ve introduced the ability to set and save part level sequencing options to be used in nesting. This is a great tool that gives users a lot more flexibility for sequence control on the part level rather than forcing a general nest level sequence on all parts.

For our punching users, we’ve improved support in HD-SuperNest for punch tool recognition so that customers can better utilize our most powerful nesting engine. We’re also very excited about our new import option in SigmaNEST for SigmaBend AP parts to integrate the bend programming more seamlessly with SigmaNEST.

Lastly, we will be introducing a new Quoting, Jobs and Inventory system to our SigmaTube SW users with full integration on the shop floor side with Load Manager and SigmaSchedule support as well as a new Tube Feedback application for tracking and updating programs at the machine.

It is critical that the data driving your processes, communication and decisions is relevant, complete and accurate.

Last question. SigmaNEST is a recognized industry leader. What can we look forward to in the coming year?

SigmaNEST has always been a customer driven company and we are looking forward this year to taking time and really improving the implementation to make it easier for our customers to get our software up and running smoothly for their business. We, of course, will have all kinds of exciting new features, but we are giving additional attention to improving this often-overlooked aspect of software delivery.

This article was originally published in the April 2024 issue of FAB Shop Magazine

Read the article in FabShop Magazine