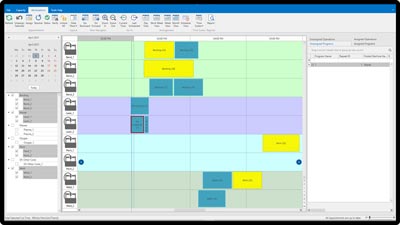

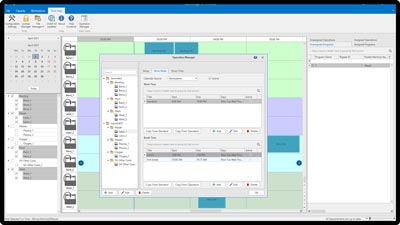

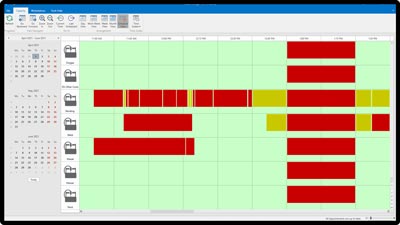

Designed for the demands of fabrication, Load Manager software now has “real-time load balancing” to divide the work efficiently for machines and secondary operations, while identifying any sequence dependencies within the timeline. The software can also be used to automatically “Resolve” the current day’s schedule to compensate for disruptions, such as machine down time or “hot” jobs, to ensure job priorities are met.

Load Manager enables optimum productivity through proactive machine scheduling and load analysis tools. Workload can be assigned (or reassigned), using drag and drop, to any machine or secondary operation. Programs can be quickly split, extended, stopped, or restarted. When used in conjunction with Color Offload, schedules are updated in real time to accurately reflect shop floor status.