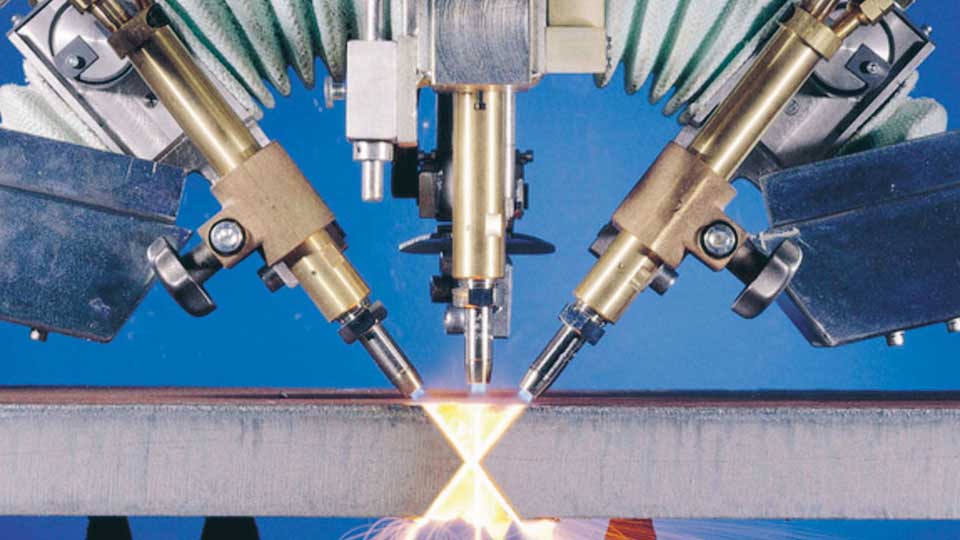

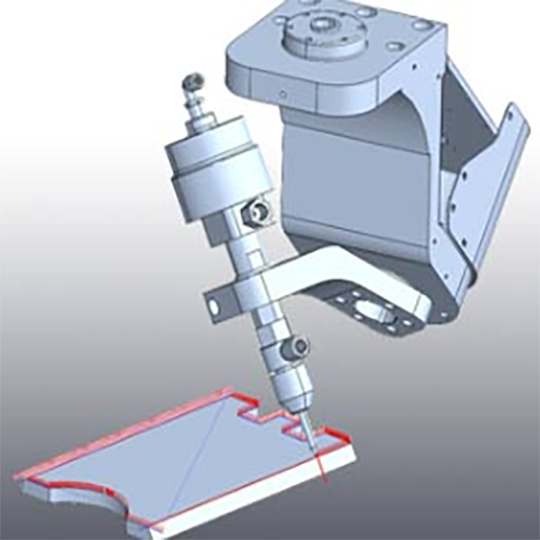

SigmaNEST offers powerful features for oxyfuel cutting machines to improve efficiency, reduce scrap and produce clean parts. SigmaNEST supports all mission-critical feature requirements including heavy plate processing, complex bevel cutting, and multi-torch cutting. SigmaNEST optimizes cutting speed while maintaining edge quality in the plate as thick as 14 inches.

SigmaNEST knows heavy plate, and SigmaNEST X1 is the culmination of over 25 years of experience programming machines to cut some of the thickest material out there. We deliver exceptional edge quality, while reducing machine wear and lowering cutting times. SigmaNEST can help you compete into the future.

SigmaNEST BHQ™ improves on market-leading hole quality cutting strategies by offering both bolt-quality precision and optimization of taper, roundness, and machine runtime. Automatic lead-in lookup is based on hole size, material thickness, process type, and power.