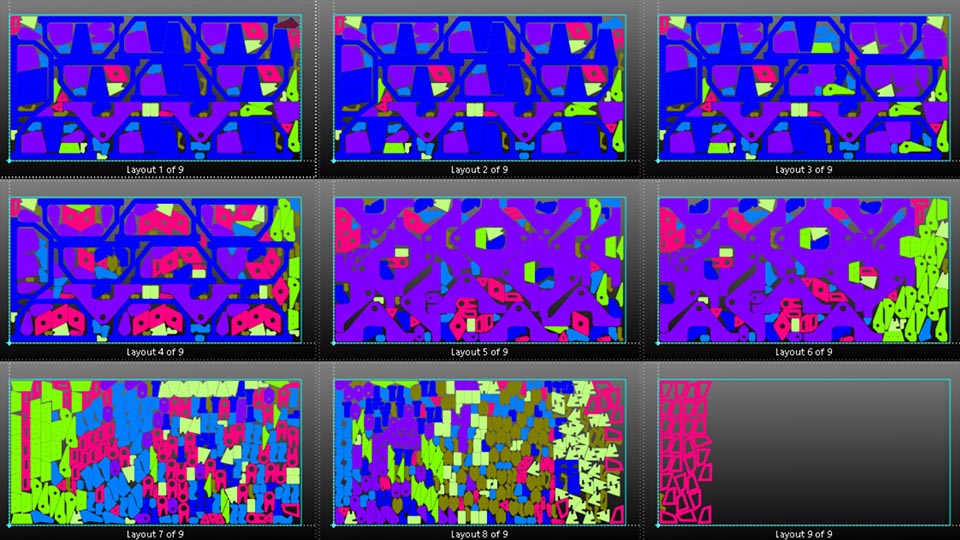

Nesting has been hailed as one of the most important technologies of the last 30 years for fabricators worldwide. And of course, it's true. Nesting software, with its automatic processing and ease of manual placement, has made it easier to obtain better material yields than ever before.

While true, there are big tradeoffs to nesting. Is it possible that you don't always want the absolute best yield? Is there a way to be more strategic and effective for when, why and how you nest parts? Let's examine some scenarios where the tightest nest isn’t the best strategy. See if any of these other priorities apply to your business today.

Nesting for Material Stability

Each material type carries unique properties. Some cutting processes can relieve internal tension in the material. Other cutting processes introduce stress into the material. In these cases, if there isn’t enough space between parts, it will lead to a weak skeleton that can be inclined to flex or twist. This can result in parts that move or shift position during cutting, thereby degrading the quality or even causing the part to be scrapped. Your nesting software needs the capability to manage part spacing to adapt to your cutting process and material. Smart programming will allow you to create parameters that work best for material type or thickness, or that automatically modify spacing in X or Y directions or prioritize cutting in relation to clamps and holders.

Nesting for Kanban

If your shop uses any Kanban methodologies to stage parts between operations, it might make sense to nest parts on the sheet in a specific order to maximize productivity overall. The minor sacrifice of extra used material pays off by improving timing, scheduling accuracy, and reducing labor costs.

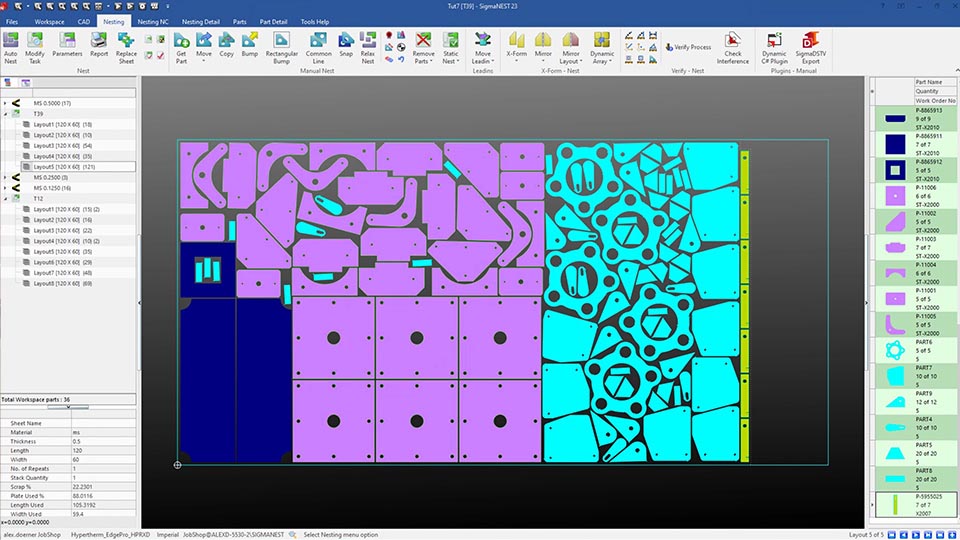

Mixing Jobs

One of the most powerful and profitable ways to maximize the value of nesting is to mix parts from different orders that call for the same material. However, there is a practical limit. Scattering 20 pallets near the cutting machine in order to stage parts for subsequent operations creates a rat’s nest at that station and starves the work downstream where they are waiting for the rest of the assembly. A better practice may be to group parts in the quantity that maintains the flow in all operations. The right nesting software should allow you to balance processing timing and good material yield of the sheet.

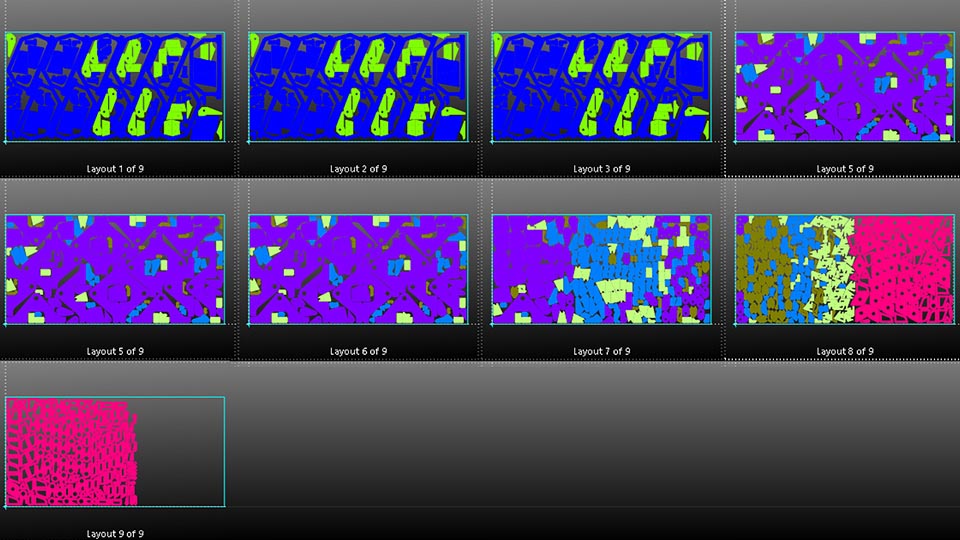

Nesting for Due Dates and Secondary Ops

It is common to have several jobs moving through the shop floor, each with its own trajectory and deadline. Some of these parts may require more downstream operations once cutting is complete. Nesting only for material yield can cause your shop to suffer if the right parts don’t get to the right workstation at the right time to make your delivery date. The power of nesting for a more efficient order for cutting and secondary processes can save both time and customer relationships. The ability to see and use delivery dates when programming your job is crucial. A nesting solution that can juggle deadlines, next ops, internal capacity, AND the inevitable disruption is even better.

Lights-Out Operation

Lights-out processing with a second work shift to maintain production can be very profitable. That is—if and only if--the machines keep running. One way to keep more machine uptime is to nest and cut more conservatively when there is not an operator available to rectify small issues. Spacing parts carefully to avoid risks of part tipping or cutting head collision can go a long way towards ending costly trips for a repair crew. Good software should be able to help you with this.

Nesting for Inventory

Like most shops, your material inventory might consist of different sheet sizes, as well as remnants left over from earlier jobs. If you always pursue the best yield above all else, you run the risk of never using up your remnants, depending on their size and shape. Nesting software that lets you book in and organize inventory, see what’s available, and select it at the right time, will make use of your remnant material so that it does not become a logistical and financial burden. Minimizing the effort of chasing inventory can be a huge savings.

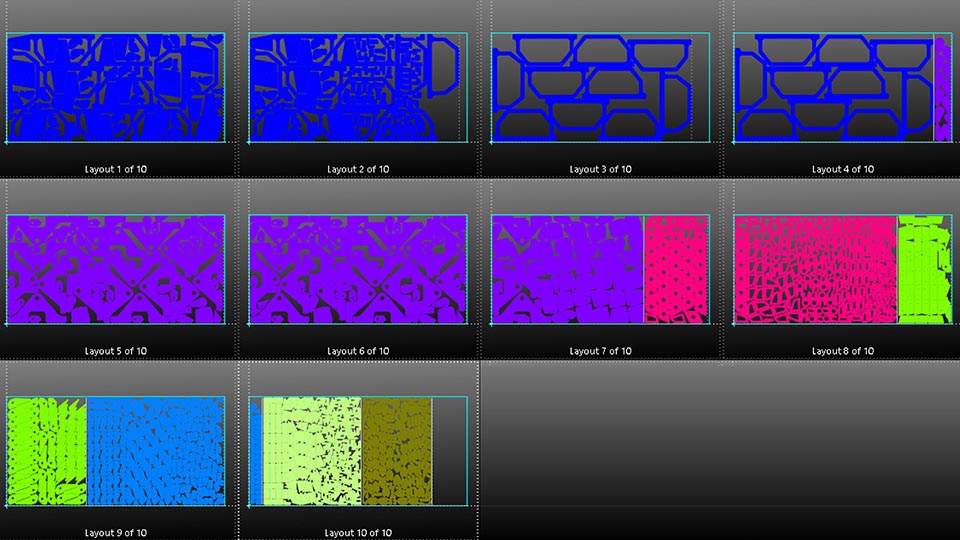

Part Orientation and Machine Compatibility

Each machine has its own unique strengths and weaknesses. Each cutting machine will impose its own restrictions on what you can do. Narrow parts may need to be placed lengthwise over multiple slats of the cutting table for your oxyfuel, plasma, laser, or waterjet. Punching machines may have tooling index angle limits which means your parts must be nested at an angle compatible with the tooling. If your machine has a drop door or parts chute, the parts may need to be rotated, processed, and aligned correctly to take advantage of the automatic part removal. The pairing of nesting software and the machine is a primary concern.

Nesting for Material Value

If the material is cheap (hardly the case anymore), it may not be worth the extra effort to chase every percentage point of yield. If the material is more valuable, the effort pays for itself. It makes sense to prioritize nesting on the materials that cost the most.

Nesting That Fits

Your needs as a company will change over time. Perhaps you intend to purchase a new or different type of cutting machine to add to your arsenal. Perhaps your shop is implementing a new ERP or management system that requires a nesting solution to work in tandem. Your operations are expanding to include press brakes or tube lasers. Perhaps material lead times have changed, and your software needs to tell inventory when it’s running low. Any of these changes will affect your entire operation from end to end. Nesting is data. The right nesting software can be powerful and adaptable data tool for optimizing your workflow for your operation. It comes down to the right nesting strategy – even if the tightest nest isn’t the top priority.

Published in Modern Metals, October 2022

"Think It Through" by Kevin Keane, Product Strategy Manager, SigmaNEST