Are We Having Leftovers Tonight? How Software Helps Reduce and Use Remnants in Your Shop

(Excerpt from an article originally appearing in the Fabricating and Metalworking magazine, written by SigmaTEK’s VP of Engineering, Glenn Durham)

One of our family hobbies is cooking and a side effects our many fancy meals is a lot of great leftovers. If you open our refrigerator you will see dozens of containers with bits and pieces left from delicious gourmet dinners. But with so many leftovers, we cannot eat them all! Sometimes a treat gets pushed to the back of the refrigerator where it remains unnoticed until moldy. Yuck!

Maybe you noticed “moldy” remnants in your shop! How do you manage remnants (drops) so they are not pushed to the back of the shop and forgotten? How do we enable our business to say, “I hope we are having leftovers (remnants) tonight!”

1. Fill the Sheet/Plate

An experienced shop manager taught me early in my fabrication career: “The best remnant is the one you do not make.” I always remind new users of this when teaching how to benefit from fabrication software. Sure, good software ensures that you manage well your remnants. But before it does that, good software helps you use full sheets instead of making remnants.

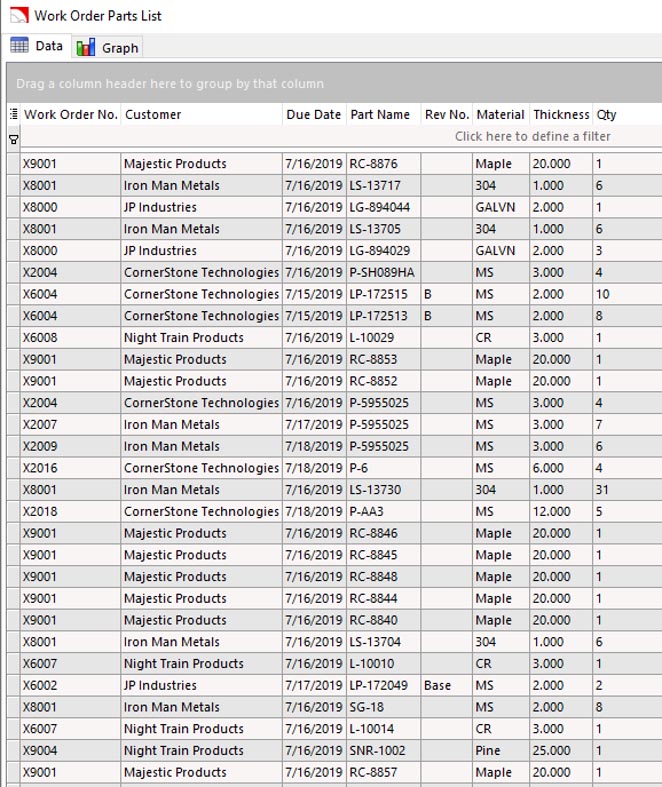

This seems easy and obvious and you might ask, “Why do I need software for that?” But as the example work order list here shows, it does not take many orders to get a huge variety of materials, thicknesses, customers, and due dates. Once you get a few dozen orders, it is nearly impossible to optimize without software.

The proper software separates parts by material, thickness, and machine, and allows you to automatically nest parts until you get full sheets. Rather than pull out another plate, load it on the machine bed, cut one part, track the remnant, and then try to use it next time, you can choose to wait to cut that extra part and see if you get more orders of the same material and thickness.

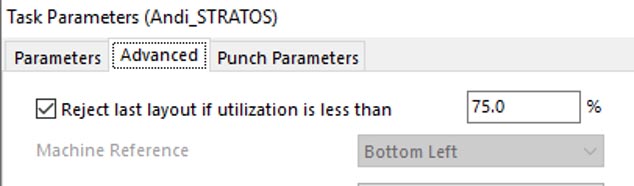

Something like this is easily handled in software with a setting like: Reject last layout if utilization is less than a certain percentage.

2. Use Your Remnants Early and Often

The second key to preventing moldy remnants around the shop is to use your remnants. Of course, this requires some level of discipline and commitment; but again, advanced CAD/CAM software helps you profit from your remnants with less difficulty.

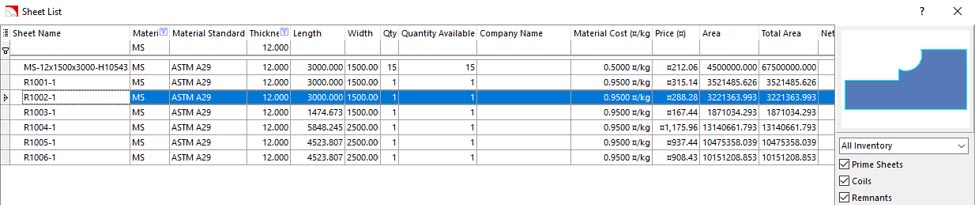

Let’s take an example where you need to cut some parts out of 12 mm mild steel. Your software shows you that you have 15 prime plates that are 1500×3000. But you also have 6 remnants of various sizes and shapes:

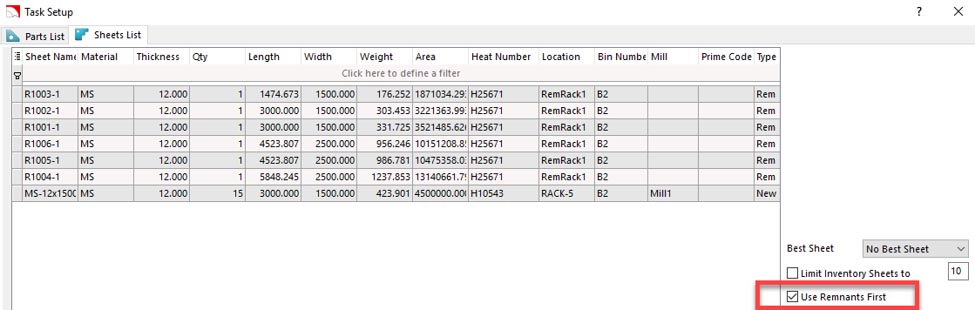

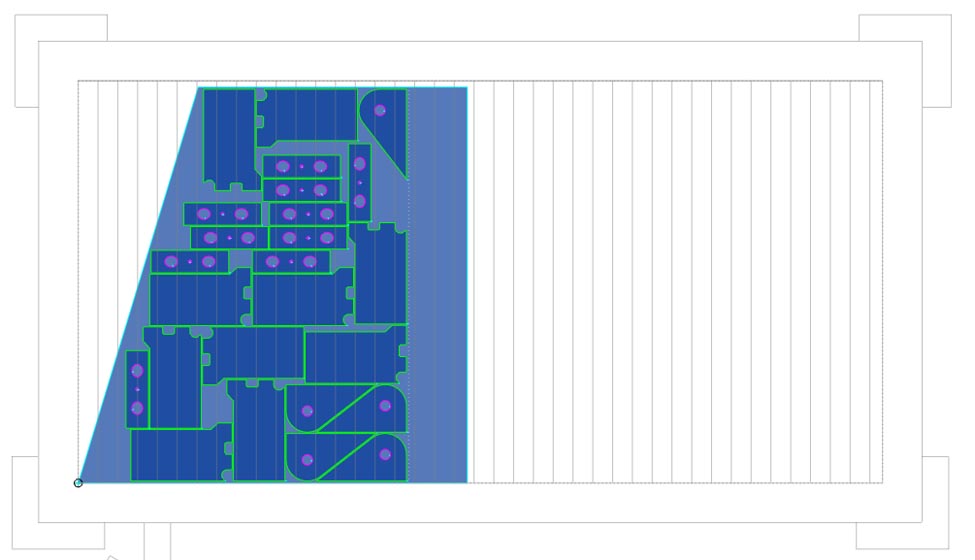

With nesting software, you simply load all these plates into a task, and tell it to use the remnants first:

The result is all of your parts fitted on the smallest remnant possible from your inventory! Instead of again using a prime plate and ADDING another remnant to the pile in the back of your shop, you actually take a remnant out of the back and enjoy some very good leftovers.

3. Conclusion

None of us wants leftovers served every meal. But it can be fun to have “leftovers night.” Everyone rummages through the refrigerator and finds a bite from earlier in the week – one that will just hit the spot for them.

It is similar when you get a nest on a remnant like shown above. Sure, it is a bit extra work to find that drop and maybe even pull it out from the bottom of the pile. But the rewards are huge. One less plate molding in the shop and your prime sheet left on the rack for the next big order. It is a win-win for everyone. Yum, delicious!